Fan Coil Unit

Ceiling Cassette Type

We aim to promote Korea's air conditioning technology worldwide

and grow into a globally competitive company through sustainable innovation.

A wireless remote controller is included as a standard feature, offering three fan speed settings (Strong, Medium, Weak) and Turbo mode for rapid cooling and heating

An automatic drain pump is built-in (600 mm of drainage capability).

Both central control and group control are available.Option

Central control can be achieved through power line communication and S-485 communication

Group control of up to 16 units can be performed using a wired remote controller.

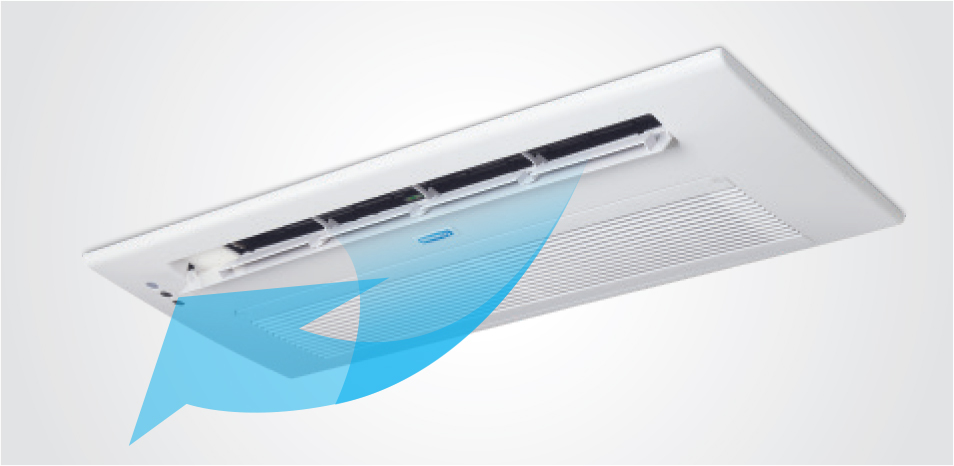

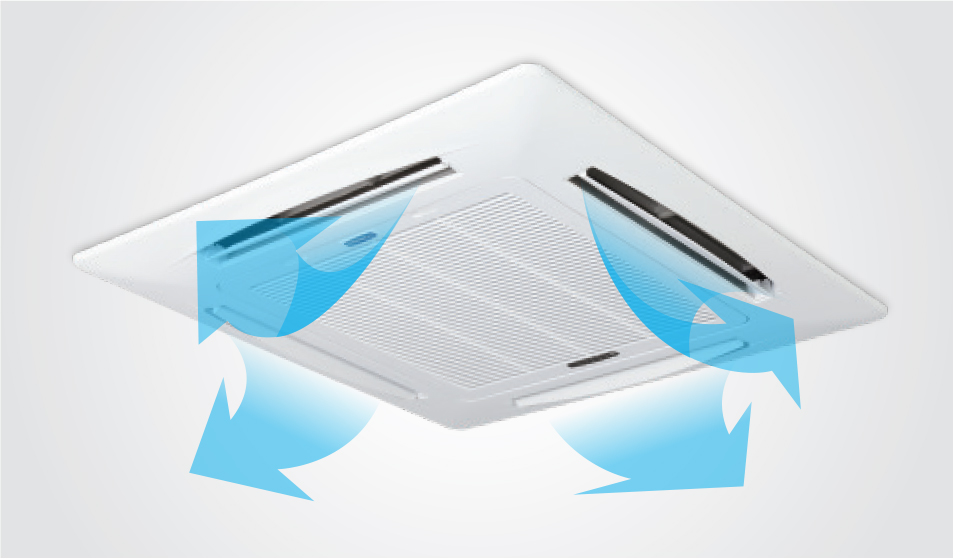

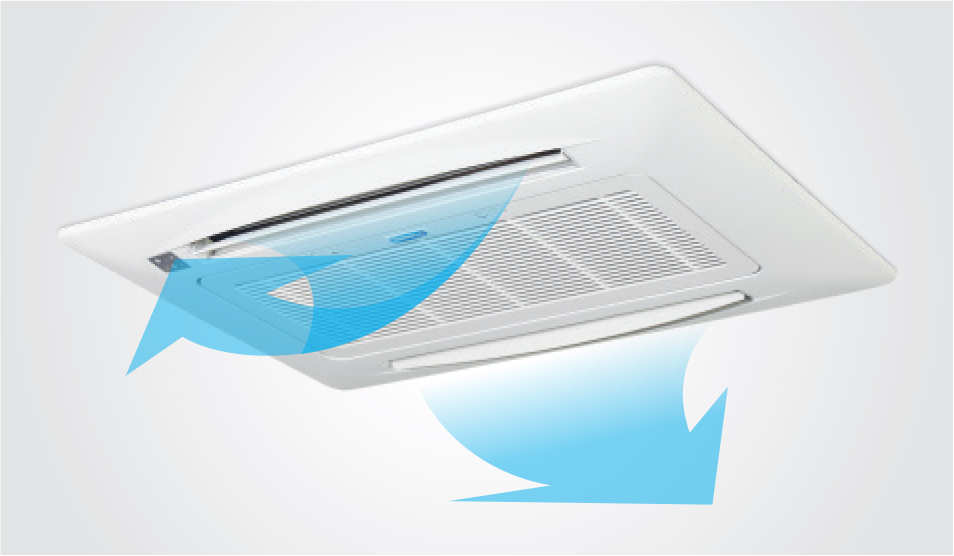

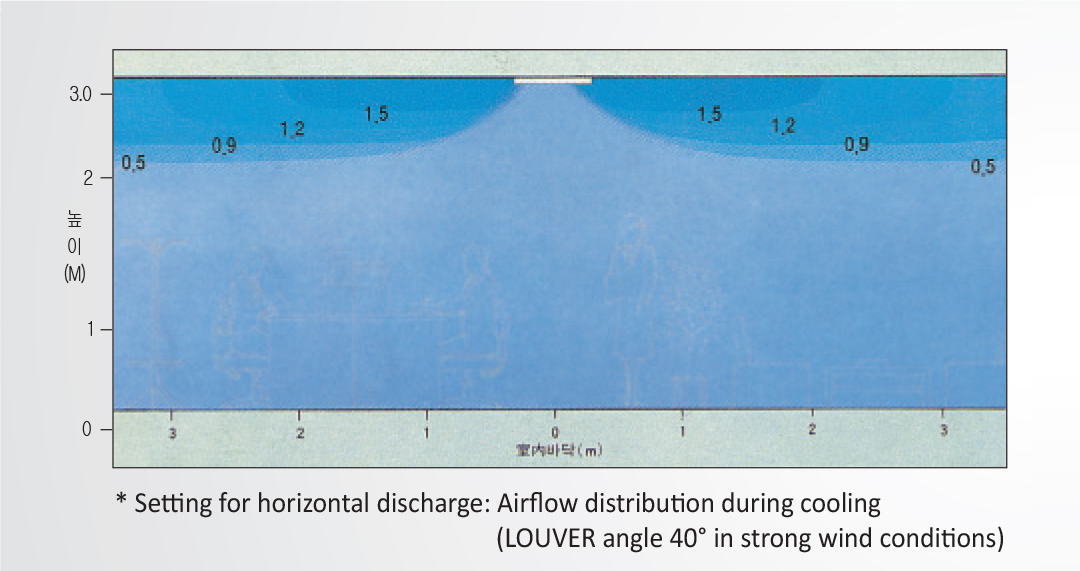

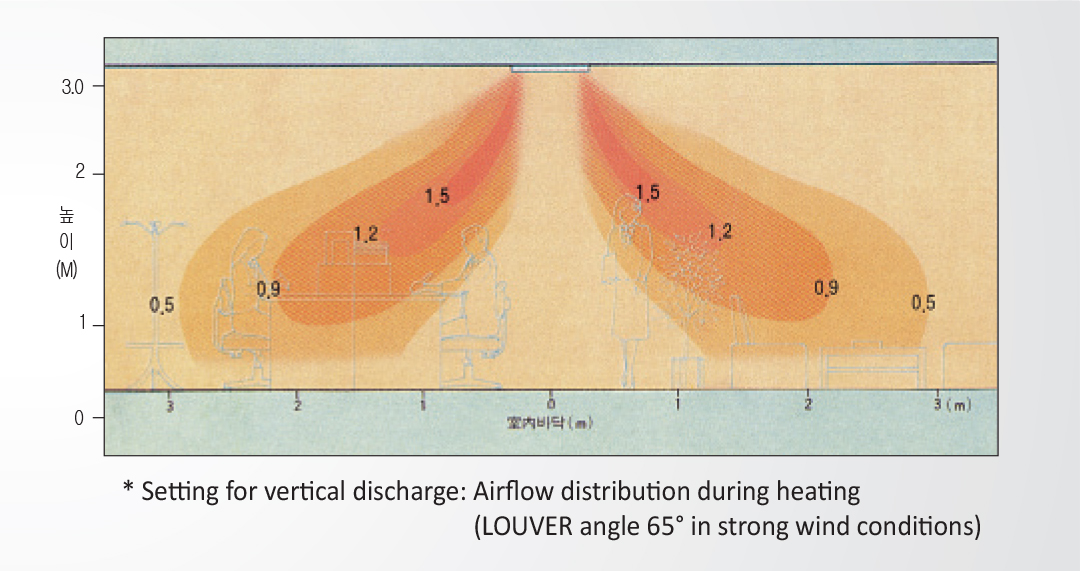

The swing blades can be adjusted to control the direction of airflow. The product also features aerodynamic blades designed to prevent direct contact between the discharged air and the ceiling, helping to prevent ceiling contamination. (Patent Acquired)

Valve installation is highly recommended due to the product's characteristics

A drain check valve is installed as standard to prevent the backflow of condensate.

The use of UV lamps provides outstanding effects in terms of sterilization, antibacterial properties, odor removal, and addressing sick building syndrome.Option

Korean Patent Registration number No. 10-1147406.

An interior grille with inspection openings can be installed.Option

Korean Patent Registration number (Utility Model) No. 10-11472719

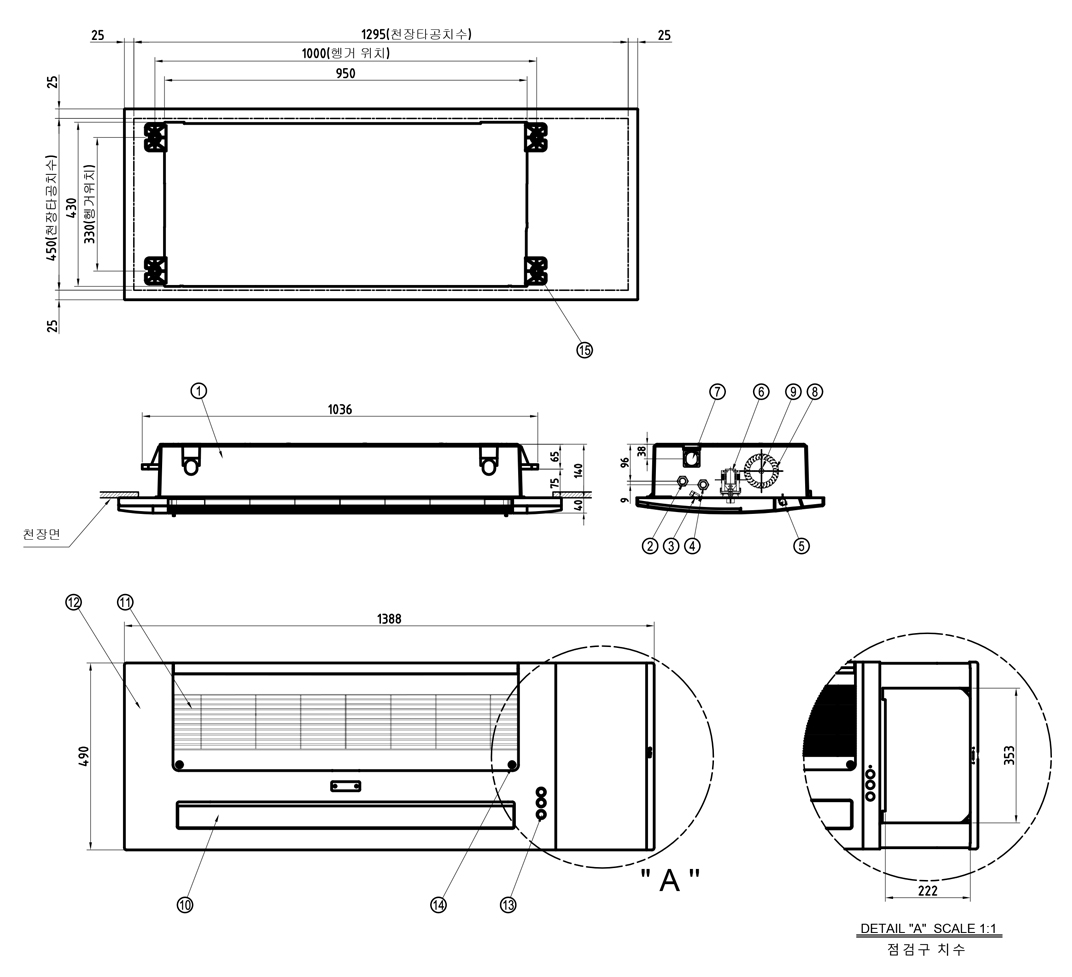

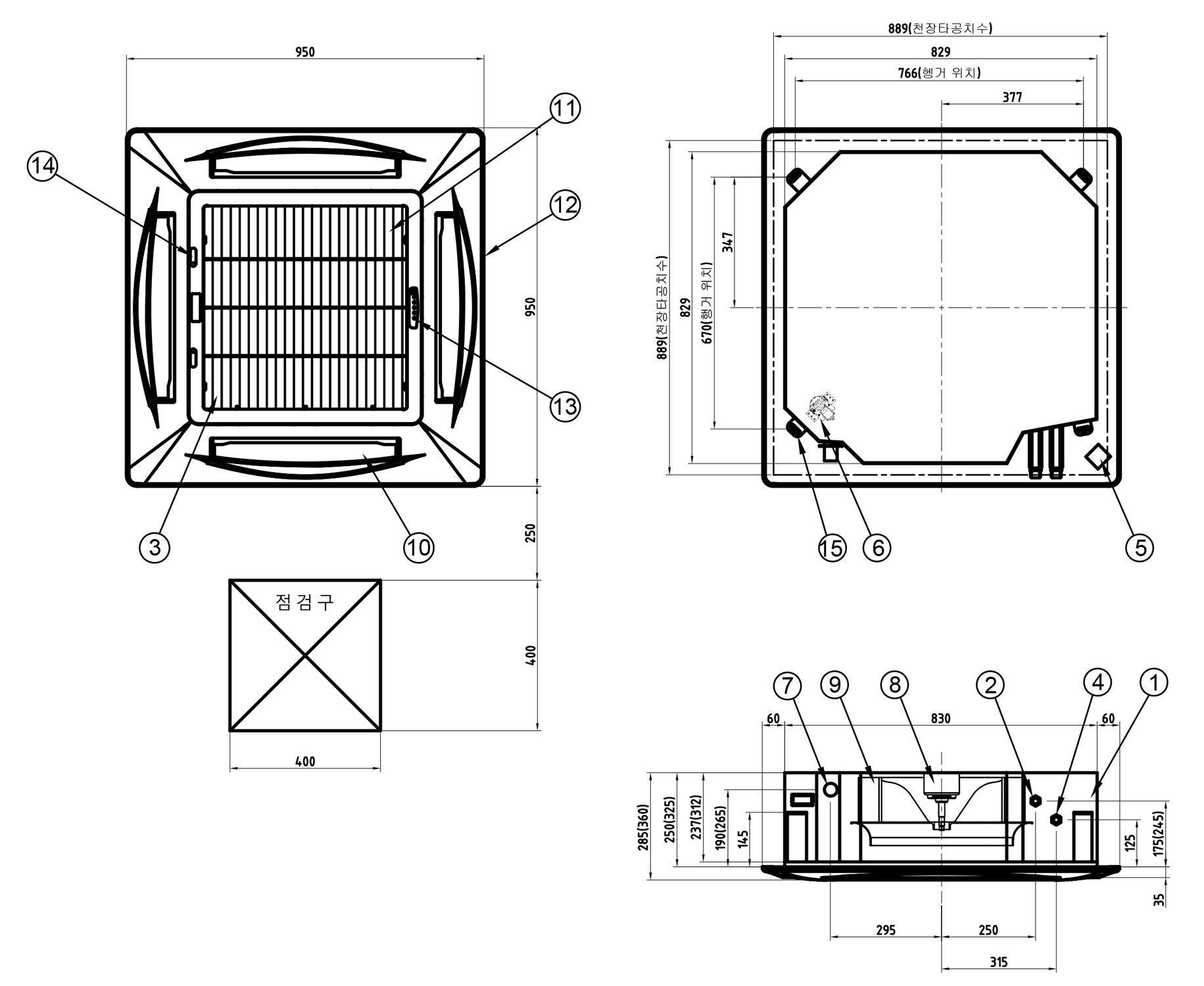

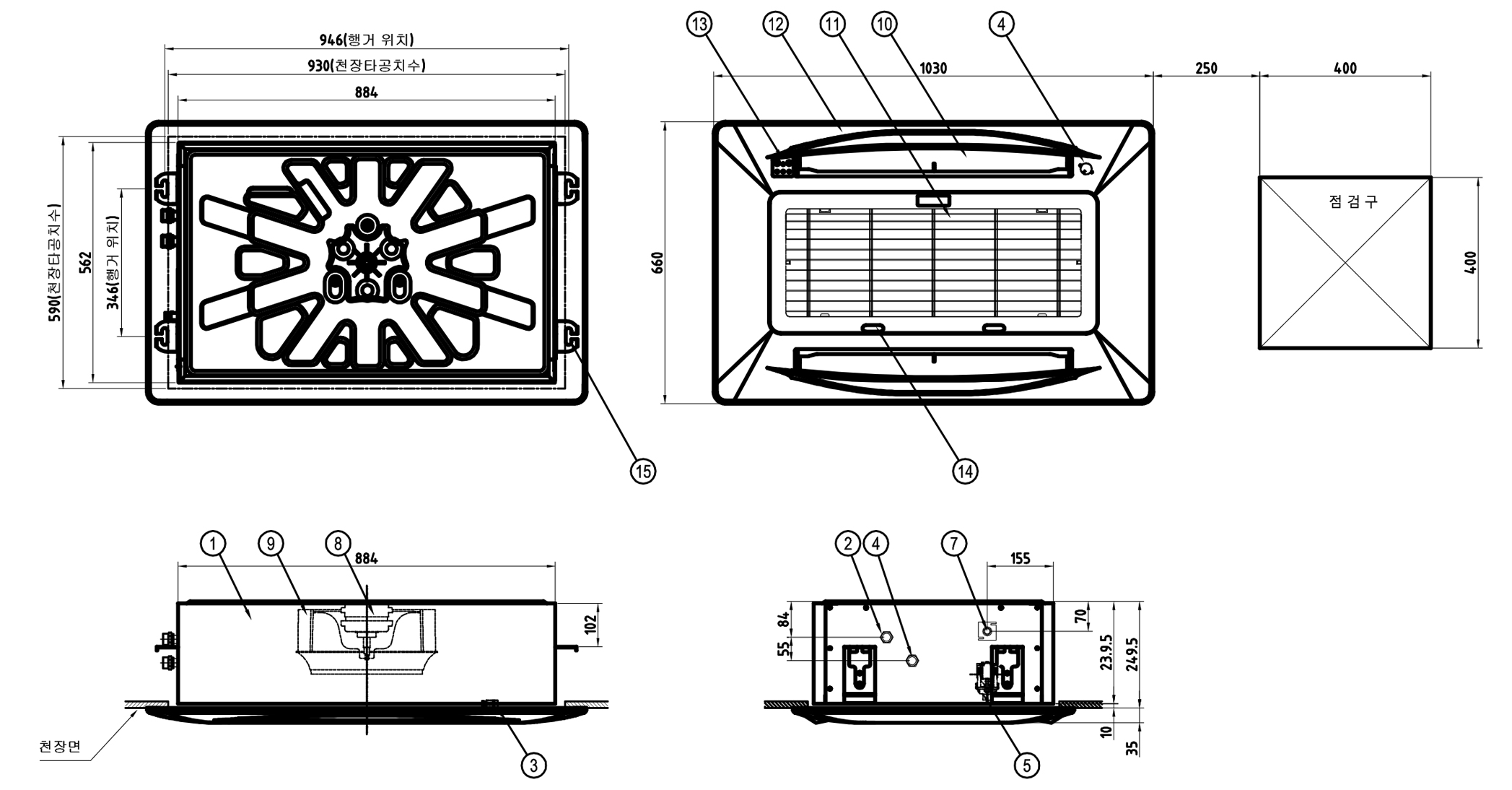

| No. | DESCRIPTION | MAT'L | Q'TY | REMARK |

|---|---|---|---|---|

| 1 | BODY CASE | ABS/HIPS | 1 | - |

| 2 | WATER OUTLET | BS | 1 | PF3/4"(20A) |

| 3 | AIR VENT | BS | 1 | PT 1/8"(SLIDING TYPE) |

| 4 | WATER INLET | BS | 1 | PF3/4"(20A) |

| 5 | STEPPING MOTOR | ASS'Y | 1 | DC12V, 15Ω |

| 6 | DRAIN PUMP | ASS’Y | 1 | 1Ø, 220V, 60Hz |

| 7 | DRAIN PIPE PORT | - | 1 | Ø16(Outer Diameter) |

| 8 | MOTOR | - | 1 | BLDC |

| 9 | BLOWER | SAN G20% | 1 | - |

| 10 | BLADE | ABS/HIPS | 1 | WHITE BEIGE |

| 11 | SUCTION GRILL | ABS/HIPS | 1 | WHITE BEIGE |

| 12 | INTERIOR GRILLE ASS'Y | ABS/HIPS | 1 | WHITE BEIGE |

| 13 | REMOTE CONTROL RECEIVER | ACRYLIC | 1 | SLIDING TYPE |

| 14 | GRILLE REMOVAL BUTTON | ABS/HIPS | 2 | SLIDING TYPE |

| 15 | HANGING BRACKET | ABS/HIPS | 4 | - |

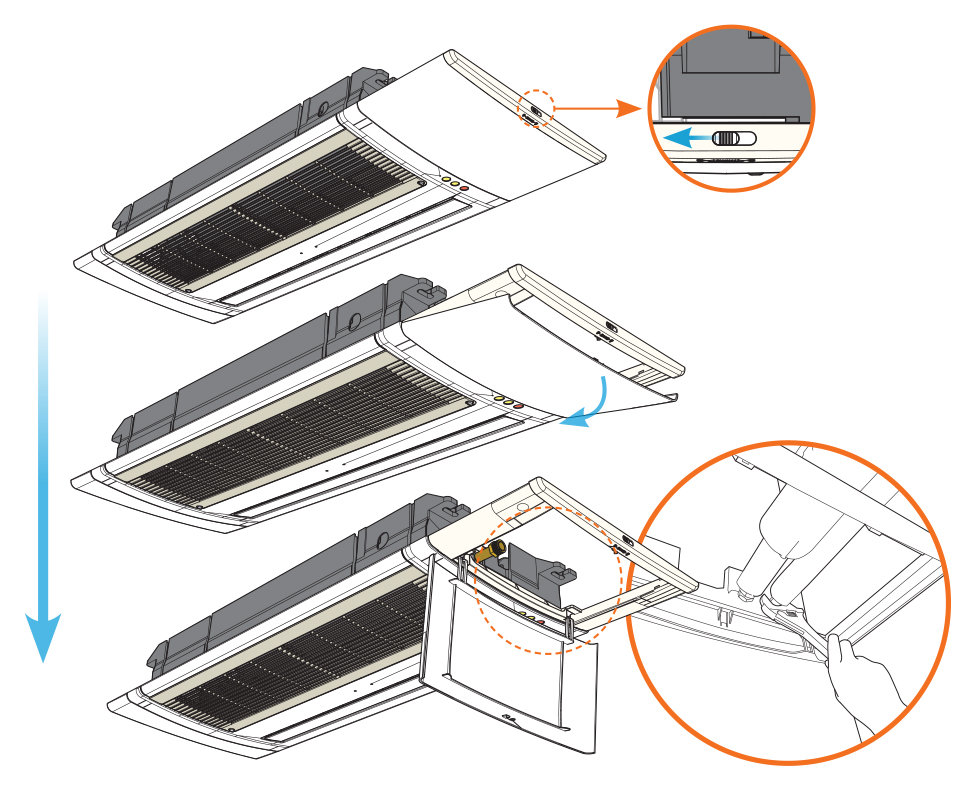

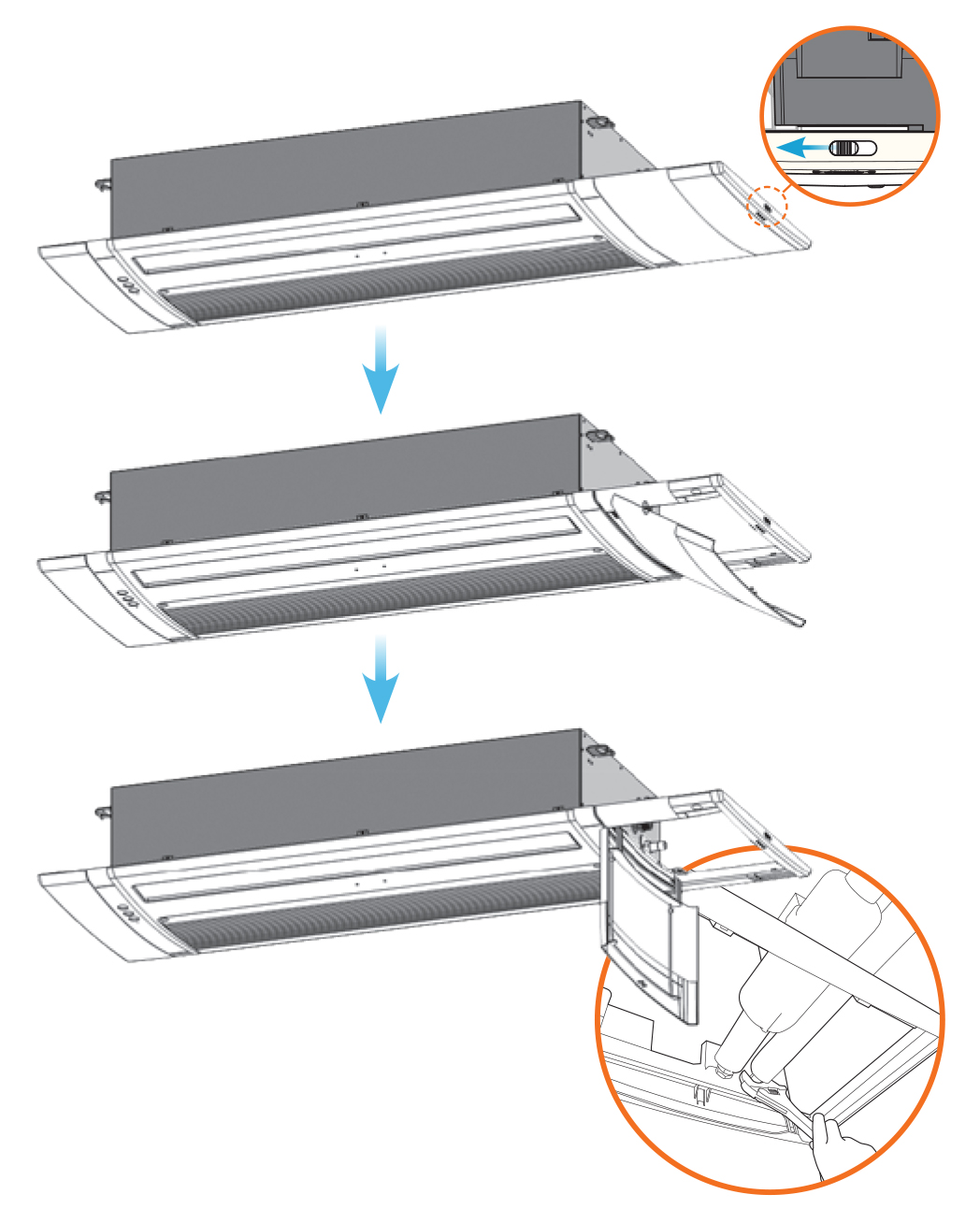

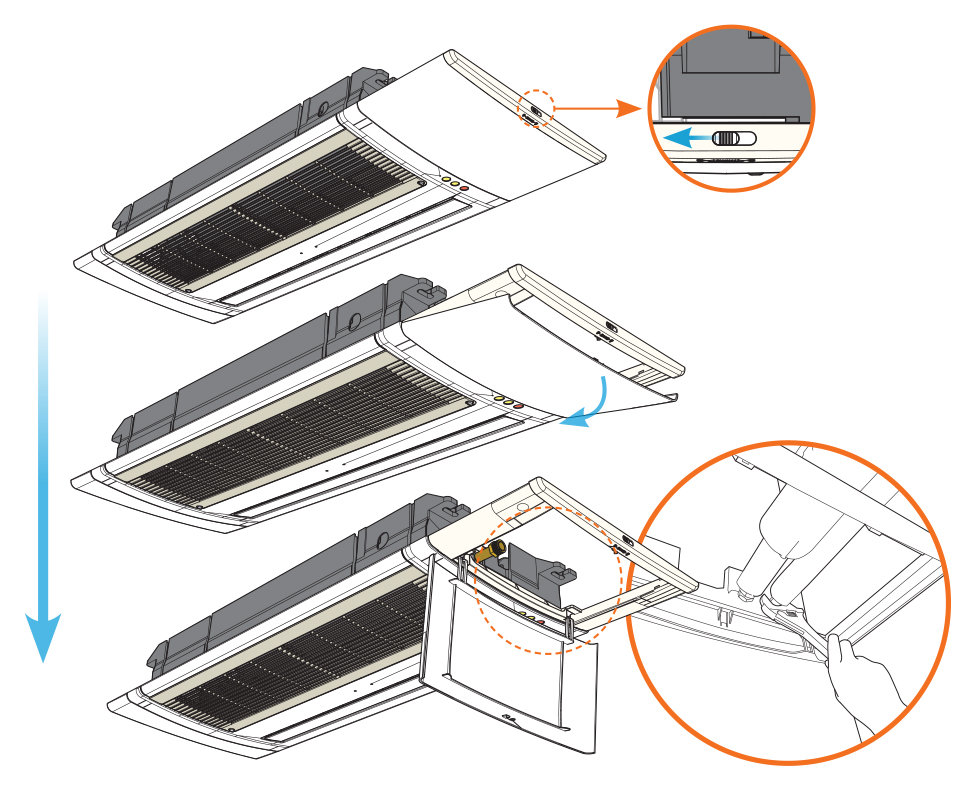

With the integration of the grille panel and inspection hole, there is no need to install a separate inspection hole on the ceiling

Installation of inspection holes can be omitted, reducing construction costs.

With no inspection openings on the ceiling surface, a seamless and integrated interior design is achievable.

Allows for convenient inspection of piping and valves.

| Category | Specifications | SFC-S2.5K | SFC-S3K | SFC-S3.5K | ||||

|---|---|---|---|---|---|---|---|---|

| Capacity | Capacity Conditions | A | B | A | B | A | B | |

| Cooling Capacity | W | 4,110 | 3,130 | 4,690 | 3,550 | 5,500 | 4,130 | |

| Kcal/h | 3,530 | 2,690 | 4,030 | 3,060 | 4,730 | 3,560 | ||

| Heating Capacity | W | 7,370 | 4,550 | 9,090 | 5,580 | 11,200 | 6,800 | |

| Kcal/h | 6,340 | 3,910 | 7,820 | 4,800 | 9,630 | 5,850 | ||

| Flow Rate | ℓ/min | 11.8 | 9.0 | 13.5 | 10.2 | 15.8 | 11.9 | |

| Head Loss | mAq | 2.6 | 1.51 | 3.4 | 1.94 | 4.66 | 2.64 | |

| Fan Blower | Type | Centrifugal Multi-Flow (Cross Flow Fan) | ||||||

| Airflow Volume | ㎥/min | 7 | 9 | 12.5 | ||||

| Motor | Type | BLDC | ||||||

| Power Consumption | W | 28 | 30.8 | 68 | ||||

| Quantity | EA | 1 | ||||||

| Heat Exchanger | Type | Integrated Multi-Pass Cross Finned Tube(Slit Fin) | ||||||

| Pipe | Inlet | A | 20A | |||||

| Outlet | A | 20A | ||||||

| Drain | 16A | |||||||

| Power Supply | Single Phase 220V 60HZ | |||||||

| Communication Line | Shield cable AWG24 x 4C | |||||||

| AIR FILTER | Vinyl Chloride (Flush type) | |||||||

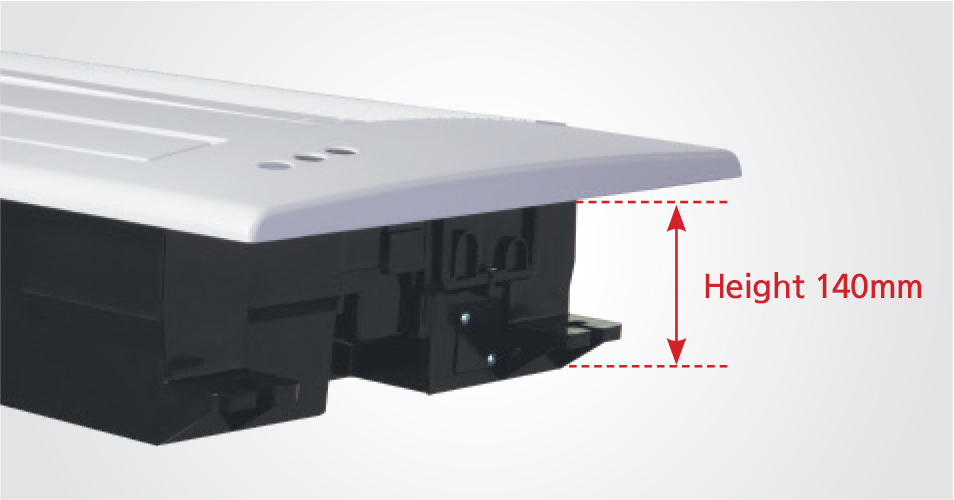

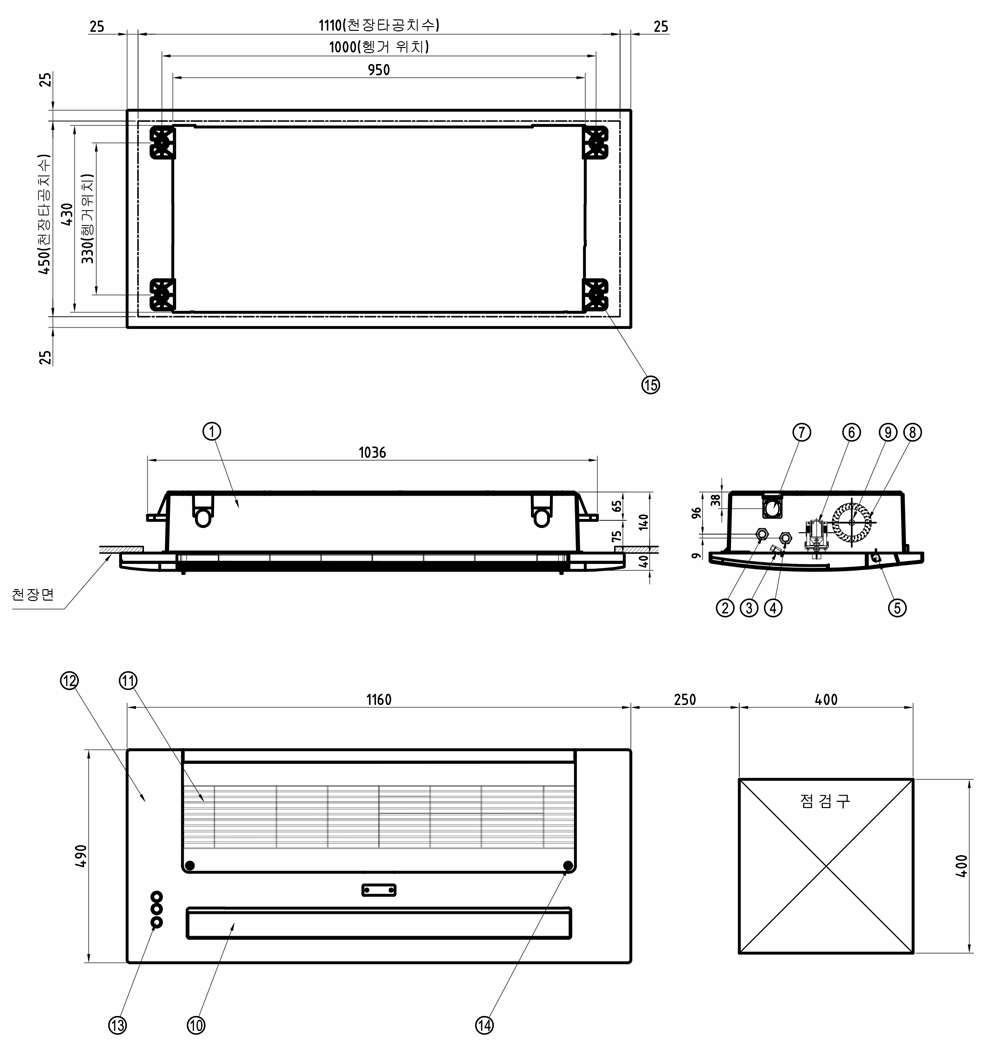

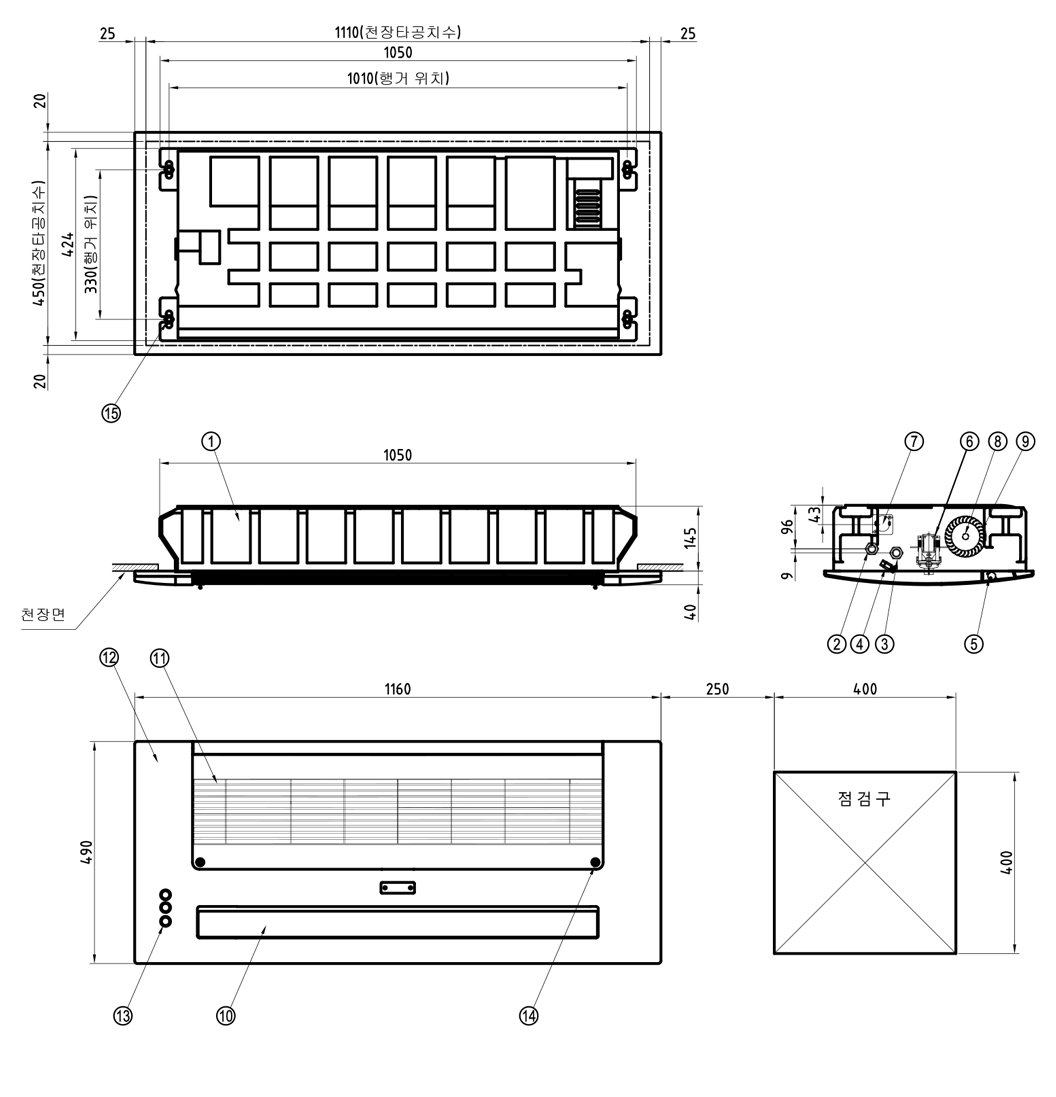

| Exterior | Main Body | DxWxH (mm) |

430 x 965 x 140 | |||||

| Panel | 490 x1160 x 40 | |||||||

| Product Weight | Kg | 12 | ||||||

| * Note | 1. Capacity Condition A - Cooling Capacity When indoor air is DB 27°C, WB 21°C, and inlet water temperature is 5°C Heating Capacity When indoor air is 18°C, and inlet water temperature is 80°C 2. Capacity Condition B - Cooling Capacity: When indoor air is DB 27°C, WB 19.5°C, and inlet water temperature is 7°C Heating Capacity: When indoor air is 21 °C, and inlet water temperature is 60°C |

|||||||

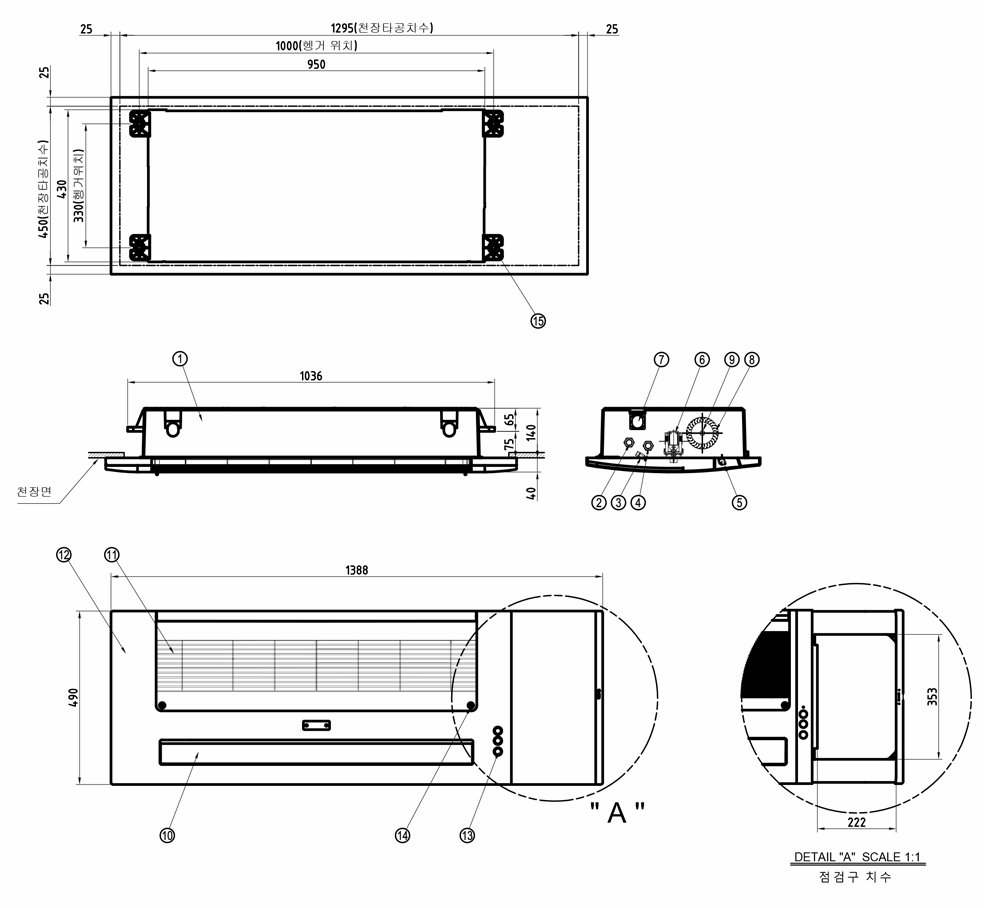

A wireless remote controller is included as a standard feature, offering three fan speed settings (Strong, Medium, Weak) and Turbo mode for rapid cooling and heating

An automatic drain pump is built-in (600 mm of drainage capability).

Both central control and group control are available.Option

Central control can be achieved through power line communication and S-485 communication

Group control of up to 16 units can be performed using a wired remote controller.

The swing blades can be adjusted to control the direction of airflow. The product also features aerodynamic blades designed to prevent direct contact between the discharged air and the ceiling, helping to prevent ceiling contamination. (Patent Acquired)

Valve installation is highly recommended due to the product's characteristics.

A drain check valve is installed as standard to prevent the backflow of condensate.

The use of UV lamps provides outstanding effects in terms of sterilization, antibacterial properties, odor removal, and addressing sick building syndrome.Option

Registered with Korean Patent No. 10-1147406.

An interior grille with inspection openings can be installed.Option

Registered with Korean Patent (Utility Model) No. 10-11472719

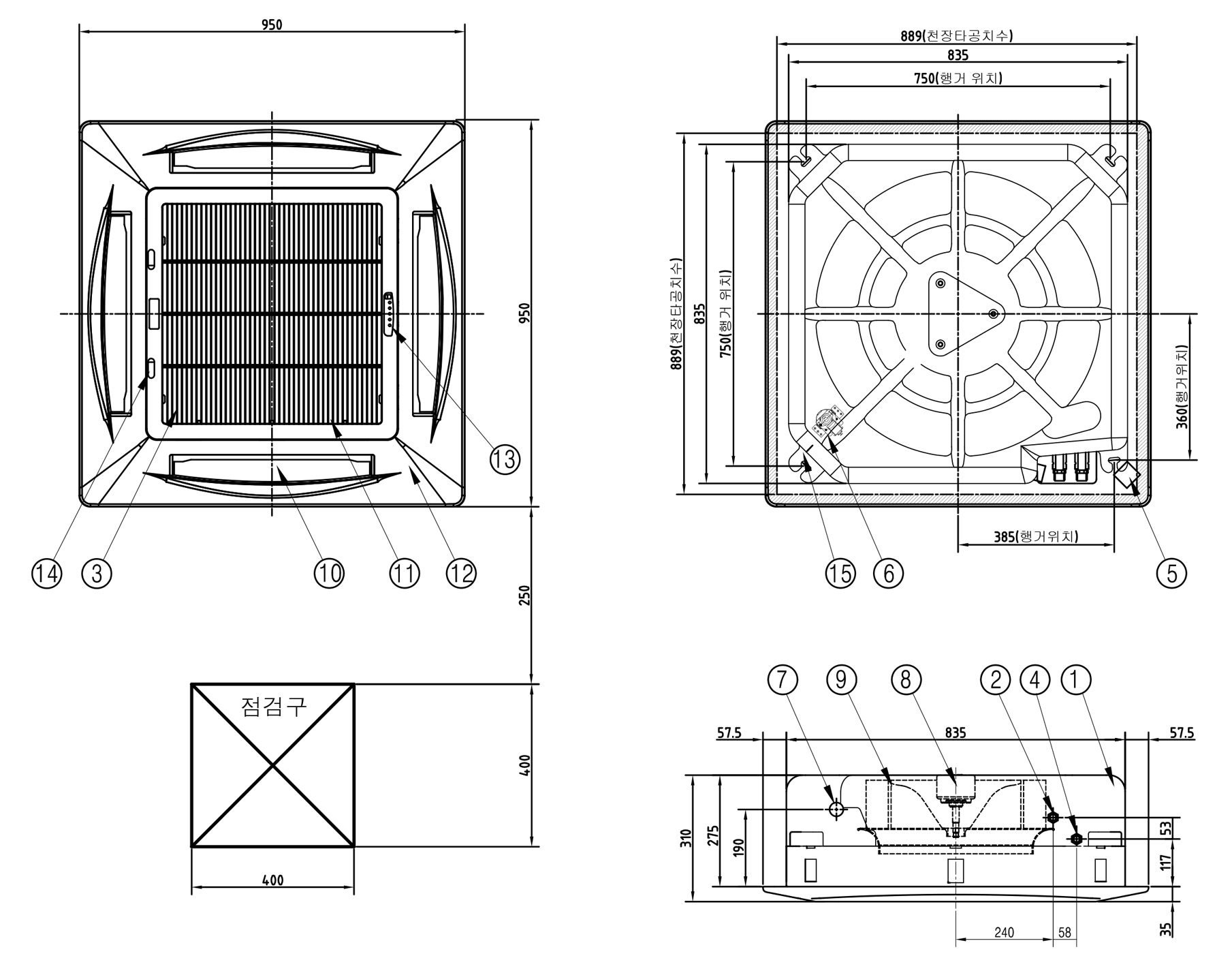

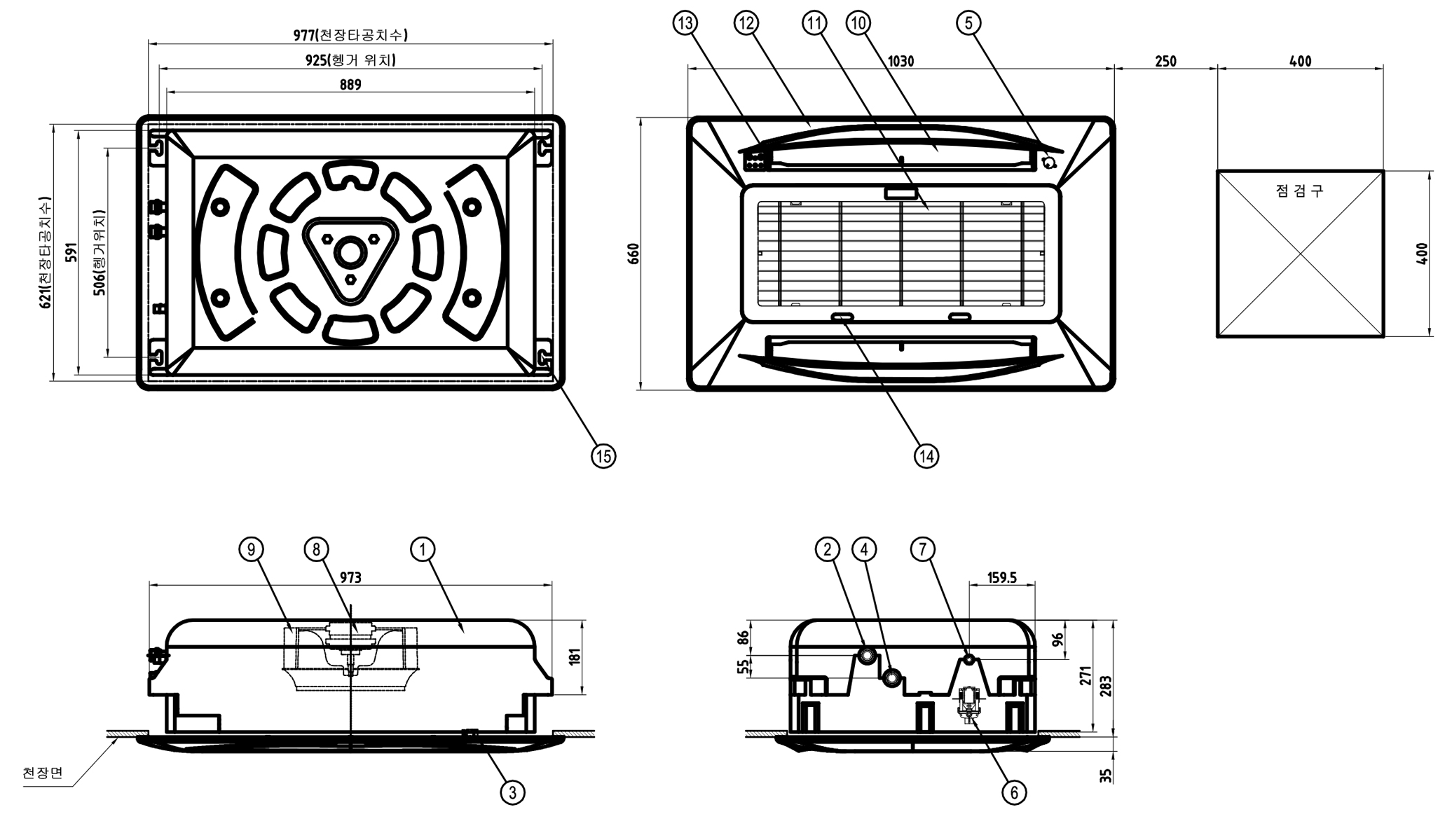

| No. | DESCRIPTION | MAT'L | Q'TY | REMARK |

|---|---|---|---|---|

| 1 | BODY CASE | GI | 1 | - |

| 2 | WATER OUTLET | BS | 1 | PF3/4"(20A) |

| 3 | AIR VENT | BS | 1 | PT 1/8"(SLIDING TYPE) |

| 4 | WATER INLET | BS | 1 | PF3/4"(20A) |

| 5 | STEPPING MOTOR | ASS'Y | 1 | DC12V, 15Ω |

| 6 | DRAIN PUMP | ASS’Y | 1 | 1Ø, 220V, 60Hz |

| 7 | DRAIN PIPE PORT | - | 1 | Ø16(Outer Diameter) |

| 8 | MOTOR | - | 1 | BLDC |

| 9 | BLOWER | SAN G20% | 1 | - |

| 10 | BLADE | ABS/HIPS | 1 | WHITE BEIGE |

| 11 | SUCTION GRILL | ABS/HIPS | 1 | WHITE BEIGE |

| 12 | INTERIOR GRILLE ASS'Y | ABS/HIPS | 1 | WHITE BEIGE |

| 13 | REMOTE CONTROL RECEIVER | ACRYLIC | 1 | SLIDING TYPE |

| 14 | GRILLE REMOVAL BUTTON | ABS/HIPS | 2 | SLIDING TYPE |

| 15 | HANGING BRACKET | GI | 4 | - |

With the integration of the grille panel and inspection hole, there is no need to install a separate inspection hole on the ceiling

Installation of inspection holes can be omitted, reducing construction costs.

With no inspection openings on the ceiling surface, a seamless and integrated interior design is achievable.

Allows for convenient inspection of piping and valves.

| Category | Specifications | SFC-S4KH | SFC-S4.5KH | |||||

|---|---|---|---|---|---|---|---|---|

| Capacity | Capacity Conditions | A | B | A | B | |||

| Cooling Capacity | W | 6,130 | 4,650 | 6,920 | 5,230 | |||

| Kcal/h | 5,270 | 4,000 | 5,950 | 4,500 | ||||

| Heating Capacity | W | 13,270 | 8,140 | 14,300 | 8,740 | |||

| Kcal/h | 11,410 | 7,000 | 12,300 | 7,520 | ||||

| Flow Rate | ℓ/min | 17.5 | 13.5 | 19.8 | 15.0 | |||

| Head Loss | mAq | 3.1 | 1.8 | 3.9 | 2.3 | |||

| Fan Blower | Type | CROSS FLOW FAN | ||||||

| Airflow Volume | ㎥/min | 13.5 | 15 | |||||

| Motor | Type | BLDC | ||||||

| Power Consumption | W | 67 | 83 | |||||

| Quantity | EA | 1 | ||||||

| Heat Exchanger | Type | Integrated Multi-Pass Cross Finned Tube(Slit Fin) | ||||||

| Pipe | Inlet | A | 20A | |||||

| Outlet | A | 20A | ||||||

| Drain | 16A | |||||||

| Power Supply | Single Phase 220V 60HZ | |||||||

| Communication Line | P.U Foam, P.E Foam, Styro Foam / Flame Retardant | |||||||

| AIR FILTER | Vinyl Chloride (Flush type) | |||||||

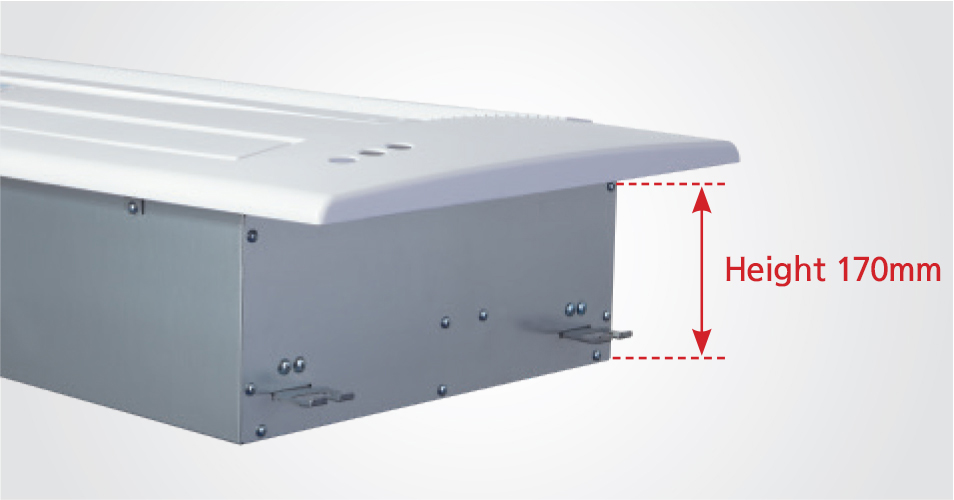

| Exterior | Main Body | DxWxH (mm) |

430x954x170 | |||||

| Panel | 490 x1160 x 40 | |||||||

| Product Weight | Kg | 22 | ||||||

| * Note | 1. Capacity Condition A - Cooling Capacity When indoor air is DB 27°C, WB 21°C, and inlet water temperature is 5°C Heating Capacity When indoor air is 18°C, and inlet water temperature is 80°C 2. Capacity Condition B - Cooling Capacity: When indoor air is DB 27°C, WB 19.5°C, and inlet water temperature is 7°C Heating Capacity: When indoor air is 21 °C, and inlet water temperature is 60°C |

|||||||

A wireless remote controller is included as a standard feature, offering three fan speed settings (Strong, Medium, Weak) and Turbo mode for rapid cooling and heating

An automatic drain pump is built-in (600 mm of drainage capability).

Both central control and group control are available.Option

Central control can be achieved through power line communication and S-485 communication

Group control of up to 16 units can be performed using a wired remote controller.

The swing blades can be adjusted to control the direction of airflow. The product also features aerodynamic blades designed to prevent direct contact between the discharged air and the ceiling, helping to prevent ceiling contamination. (Patent Acquired)

Valve installation is highly recommended due to the product's characteristics

A drain check valve is installed as standard to prevent the backflow of condensate.

The use of UV lamps provides outstanding effects in terms of sterilization, antibacterial properties, odor removal, and addressing sick building syndrome.Option

Registered with Korean Patent No. 10-1147406.

An interior grille with inspection openings can be installed.Option

Registered with Korean Patent (Utility Model) No. 10-11472719

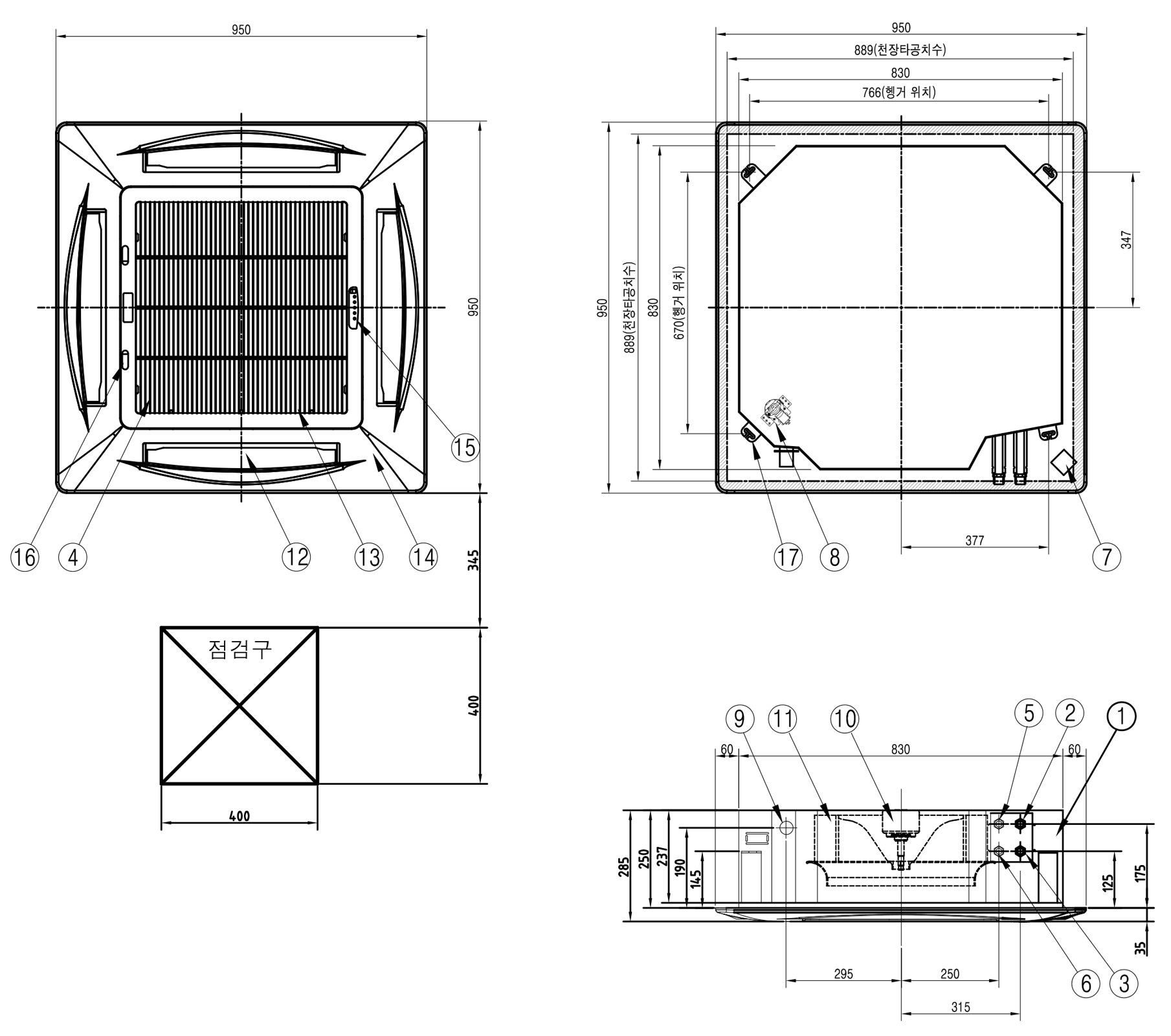

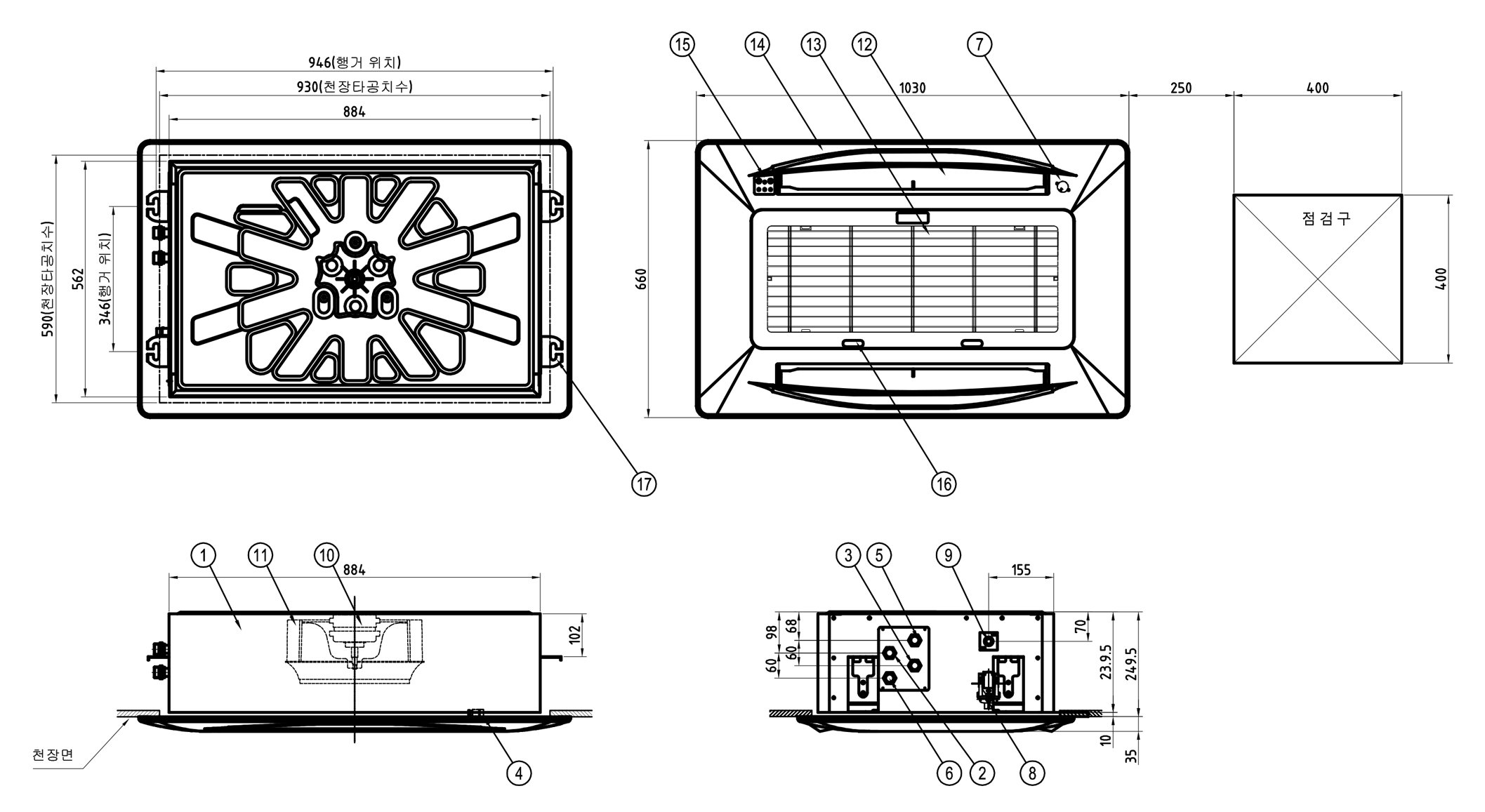

| No. | DESCRIPTION | MAT'L | Q'TY | REMARK |

|---|---|---|---|---|

| 1 | BODY CASE | EPP | 1 | - |

| 2 | WATER OUTLET | BS | 1 | PF3/4"(20A) |

| 3 | AIR VENT | BS | 1 | PT 1/8"(SLIDING TYPE) |

| 4 | WATER INLET | BS | 1 | PF3/4"(20A) |

| 5 | STEPPING MOTOR | ASS'Y | 1 | DC12V, 15Ω |

| 6 | DRAIN PUMP | ASS’Y | 1 | 1Ø, 220V, 60Hz |

| 7 | DRAIN PIPE PORT | - | 1 | Ø16(Outer Diameter) |

| 8 | MOTOR | - | 1 | BLDC |

| 9 | BLOWER | SAN G20% | 1 | - |

| 10 | BLADE | ABS/HIPS | 1 | WHITE BEIGE |

| 11 | SUCTION GRILL | ABS/HIPS | 1 | WHITE BEIGE |

| 12 | INTERIOR GRILLE ASS'Y | ABS/HIPS | 1 | WHITE BEIGE |

| 13 | REMOTE CONTROL RECEIVER | ACRYLIC | 1 | SLIDING TYPE |

| 14 | GRILLE REMOVAL BUTTON | ABS/HIPS | 2 | SLIDING TYPE |

| 15 | HANGING BRACKET | EPP | 4 | - |

With the integration of the grille panel and inspection hole, there is no need to install a separate inspection hole on the ceiling

Installation of inspection holes can be omitted, reducing construction costs.

With no inspection openings on the ceiling surface, a seamless and integrated interior design is achievable.

Allows for convenient inspection of piping and valves.

| Category | Specifications | SFC-ES2.5K | SFC-ES3K | SFC-ES3.5K | ||||

|---|---|---|---|---|---|---|---|---|

| Capacity | Capacity Conditions | A | B | A | B | A | B | |

| Cooling Capacity | W | 4,110 | 3,130 | 4,690 | 3,550 | 5,500 | 4,130 | |

| Kcal/h | 3,530 | 2,690 | 4,030 | 3,060 | 4,730 | 3,560 | ||

| Heating Capacity | W | 7,370 | 4,550 | 9,090 | 5,580 | 11,200 | 6,800 | |

| Kcal/h | 6,340 | 3,910 | 7,820 | 4,800 | 9,630 | 5,850 | ||

| Flow Rate | ℓ/min | 11.8 | 9.0 | 13.5 | 10.2 | 15.8 | 11.9 | |

| Head Loss | mAq | 2.6 | 1.51 | 3.4 | 1.94 | 4.66 | 2.64 | |

| Fan Blower | Type | Centrifugal Multi-Flow (Cross Flow Fan) | ||||||

| Airflow Volume | ㎥/min | 7 | 9 | 12.5 | ||||

| Motor | Type | BLDC | ||||||

| Power Consumption | W | 28 | 30.8 | 68 | ||||

| Quantity | EA | 1 | ||||||

| Heat Exchanger | Type | Integrated Multi-Pass Cross Finned Tube(Slit Fin) | ||||||

| Pipe | Inlet | A | 20A | |||||

| Outlet | A | 20A | ||||||

| Drain | 16A | |||||||

| Power Supply | Single Phase 220V 60HZ | |||||||

| Communication Line | Shield cable AWG24 x 4C | |||||||

| AIR FILTER | Vinyl Chloride (Flush type) | |||||||

| Exterior | Main Body | DxWxH (mm) |

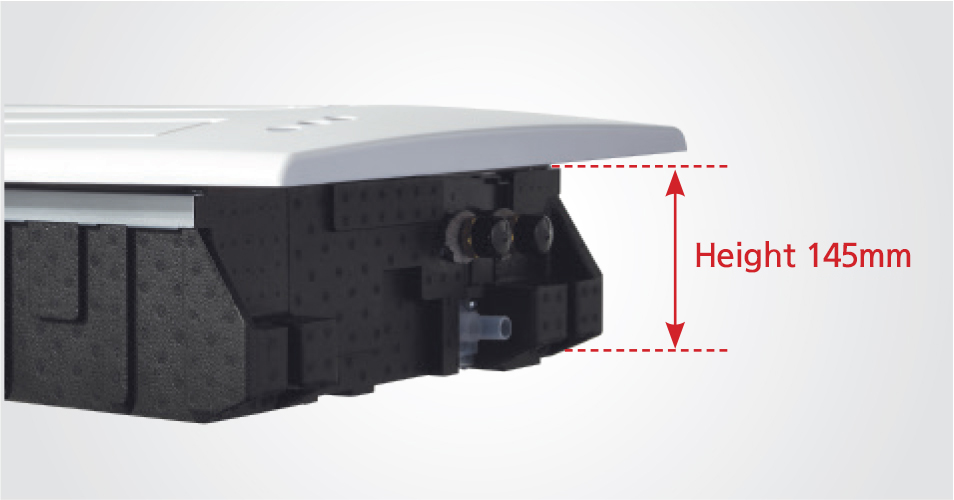

410 x 950 x 145 | |||||

| Panel | 490 x 1160 x 40 | |||||||

| Product Weight | Kg | 12 | ||||||

| * Note | 1. Capacity Condition A - Cooling Capacity When indoor air is DB 27°C, WB 21°C, and inlet water temperature is 5°C Heating Capacity When indoor air is 18°C, and inlet water temperature is 80°C 2. Capacity Condition B - Cooling Capacity: When indoor air is DB 27°C, WB 19.5°C, and inlet water temperature is 7°C Heating Capacity: When indoor air is 21 °C, and inlet water temperature is 60°C |

|||||||

An automatic drain pump is built-in (600 mm of drainage capability).

A drain check valve is installed as standard to prevent the backflow of condensate.

An independent control grille panel can be installed.Option

With the application of a BLDC motor as a standard specification, power consumption can be reduced by more than 30% compared to an AC motor with low power and high efficiency.

Both central control and group control are available.Option

Central control can be achieved through power line communication and S-485 communication

Group control of up to 16 units can be performed using a wired remote controller.

A wireless remote controller is included as a standard feature, offering three fan speed settings (Strong, Medium, Weak) and Turbo mode for rapid cooling and heating

For energy savings, installation of On/Off valves for each product is recommended.Option

These control the flow in coordination with the unit's operation preventing condensation issues during cooling, and reducing unnecessary operation cycles of the circulation pump

The use of UV lamps provides outstanding effects in terms of sterilization antibacterial properties, odor removal, and addressing sick building syndrome.Option

Korean Patent Registration No. 10-1147406.

| No. | DESCRIPTION | MAT'L | Q'TY | REMARK |

|---|---|---|---|---|

| 1 | BODY CASE | GI | 1 | - |

| 2 | WATER OUTLET | BS | 1 | PF3/4"(20A) |

| 3 | AIR VENT | BS | 1 | PT 1/8"(SLIDING TYPE) |

| 4 | WATER INLET | BS | 1 | PF3/4"(20A) |

| 5 | STEPPING MOTOR | ASS'Y | 1 | DC12V, 15Ω |

| 6 | DRAIN PUMP | ASS’Y | 1 | 1Ø, 220V, 60Hz |

| 7 | DRAIN PIPE PORT | - | 1 | Ø16(Outer Diameter) |

| 8 | MOTOR | - | 1 | BLDC |

| 9 | BLOWER | SAN G20% | 1 | - |

| 10 | BLADE | ABS/HIPS | 4 | WHITE BEIGE |

| 11 | SUCTION GRILL | ABS/HIPS | 1 | WHITE BEIGE |

| 12 | INTERIOR GRILLE ASS'Y | ABS/HIPS | 1 | WHITE BEIGE |

| 13 | REMOTE CONTROL RECEIVER | ACRYLIC | 1 | SLIDING TYPE |

| 14 | GRILLE REMOVAL BUTTON | ABS/HIPS | 2 | SLIDING TYPE |

| 15 | HANGING BRACKET | GI | 4 | - |

| Category | Specifications | SFC-3KB | SFC-4KB | SFC-5KB | SFC-6KB | SFC-8KB | SFC-10KB | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity | Capacity Conditions | A | B | A | B | A | B | A | B | A | B | A | B | |

| Cooling Capacity | W | 4,840 | 3,660 | 6,690 | 5,000 | 7,990 | 6,110 | 9,610 | 7,270 | 12,640 | 9,480 | 15,360 | 11,630 | |

| Kcal/h | 4,160 | 3,150 | 5,750 | 4,300 | 6,870 | 5,250 | 8,260 | 6,550 | 10,870 | 8,150 | 13,210 | 10,000 | ||

| Heating Capacity | W | 9,660 | 5,870 | 13,200 | 7,970 | 15,920 | 9,770 | 19,060 | 11,630 | 24,880 | 15,120 | 29,540 | 18,020 | |

| Kcal/h | 8,310 | 5,050 | 11,350 | 6,850 | 13,690 | 8,400 | 16,390 | 10,000 | 21,390 | 13,000 | 25,400 | 15,500 | ||

| Flow Rate | ℓ/min | 13.9 | 11.0 | 19.2 | 14.0 | 23.0 | 18.0 | 27.6 | 21.0 | 36.3 | 27.0 | 44.0 | 33.3 | |

| Head Loss | mAq | 3.1 | 2.0 | 6.0 | 3.2 | 2.1 | 1.3 | 3.1 | 1.8 | 5.5 | 3.0 | 13.4 | 7.7 | |

| Fan Blower | Type | Single Suction TURBO type | ||||||||||||

| SIZE | A | Ø480 | ||||||||||||

| Airflow Volume | ㎥/min | 13 | 16 | 19 | 22 | 26 | 33 | |||||||

| Drive Type | Direct Drive Motor | |||||||||||||

| Quantity | EA | 1 | ||||||||||||

| Motor | Type | BLDC Semi-Enclosed Type (8 poles, Class E insulation) | ||||||||||||

| Power Consumption | W | 20 | 37 | 55 | 80 | 125 | 186 | |||||||

| Quantity | EA | 1 | ||||||||||||

| Heat Exchanger | Type | Integrated Multi-Pass Cross Finned Tube(Slit Fin) | ||||||||||||

| Pipe | Inlet | A | PF 3/4" (20A) | |||||||||||

| Outlet | A | PF 3/4" (20A) | ||||||||||||

| Drain | Ø16 (Outer Diameter) / Built-in Drain Pump (10 W) / Head 600 mm (from Outlet) | |||||||||||||

| External Material | Main Body: Zinc-Coated Steel Plate (0.8 t, 1.0 t) / Grille Panel: Injection Molded (HIPS, ABS Material) | |||||||||||||

| Air Volume Control | Turbo, Strong, Medium, Weak, Automatic Wireless Remote Controller (Wired remote controller is optional) | |||||||||||||

| Power Supply | Single Phase 220V 60HZ | |||||||||||||

| AIR FILTER | Vinyl Chloride (Flush type) | |||||||||||||

| Discharge Swing Motor | DC 12V STEPPING MOTOR | |||||||||||||

| Dimensions | Main Body | DxWxH (mm) |

830 X 830 X 250 | 830 X 830 X 320 | ||||||||||

| Panel | 950 X 950 X 35 | |||||||||||||

| Product Weight | Kg | 21.5 | 23 | 30 | ||||||||||

| * Note | 1. Capacity Condition A - Cooling Capacity When indoor air is DB 27°C, WB 21°C, and inlet water temperature is 5°C Heating Capacity When indoor air is 18°C, and inlet water temperature is 80°C 2. Capacity Condition B - Cooling Capacity: When indoor air is DB 27°C, WB 19.5°C, and inlet water temperature is 7°C Heating Capacity: When indoor air is 21 °C, and inlet water temperature is 60°C |

|||||||||||||

Use of eco-friendly heat-resistant and corrosion-resistant materials

EPP (Expanded Poly-Propylene) is resistant to heat, provides excellent insulation and minimizes heat loss, resulting in outstanding performance.

EPP inhibits oxidation and prevents corrosion, even when used for a long period of time

Use of lightweight materials

Using lightweight materials compared to traditional steel products can save construction costs.

Density Comparison: Steel (7.85 kg/㎥) >> EPP (0.12 kg/㎥)

With the application of a BLDC motor as a standard specification

power consumption can be reduced by more than 30% compared to an AC motor with low power and high efficiency.

A wireless remote controller is included as a standard feature, offering three fan speed settings (Strong, Medium, Weak) and Turbo mode for rapid cooling and heating

An automatic drain pump is built-in (600 mm of drainage capability).

A drain check valve is installed as standard to prevent the backflow of condensate.

An independent control grille panel can be installed.Option

For energy savings, installation of On/Off valves for each unit is recommended.Option

These control the flow in coordination with the unit's operation preventing condensation issues during cooling, and reducing unnecessary operation cycles of the circulation pump

Both central control and group control are available.Option

Central control can be achieved through power line communication and S-485 communication.

Group control of up to 16 units can be performed using a wired remote controller.

The use of UV lamps provides outstanding effects in terms of sterilization, antibacterial properties, odor removal, and addressing sick building syndrome.Option

Korean Patent Registration No. 10-1147406

Registered 4 domestic patents related to EPP

2 Utility Model atents: No. 10-1266268, No. 10-1280448

2 Design Patents: No. 30-0694028, No. 30-0694029

| No. | DESCRIPTION | MAT'L | Q'TY | REMARK |

|---|---|---|---|---|

| 1 | BODY CASE | EPP | 1 | - |

| 2 | WATER OUTLET | BS | 1 | PF3/4"(20A) |

| 3 | AIR VENT | BS | 1 | PT 1/8"(SLIDING TYPE) |

| 4 | WATER INLET | BS | 1 | PF3/4"(20A) |

| 5 | STEPPING MOTOR | ASS'Y | 1 | DC12V, 15Ω |

| 6 | DRAIN PUMP | ASS’Y | 1 | 1Ø, 220V, 60Hz |

| 7 | DRAIN PIPE PORT | - | 1 | Ø16(Outer Diameter) |

| 8 | MOTOR | - | 1 | BLDC |

| 9 | BLOWER | SAN G20% | 1 | - |

| 10 | BLADE | ABS/HIPS | 4 | WHITE BEIGE |

| 11 | SUCTION GRILL | ABS/HIPS | 1 | WHITE BEIGE |

| 12 | INTERIOR GRILLE ASS'Y | ABS/HIPS | 1 | WHITE BEIGE |

| 13 | REMOTE CONTROL RECEIVER | ACRYLIC | 1 | SLIDING TYPE |

| 14 | GRILLE REMOVAL BUTTON | ABS/HIPS | 2 | SLIDING TYPE |

| 15 | HANGING BRACKET | EPP | 4 | - |

| Category | Specifications | SFC-E3K | SFC-E4K | SFC-E5K | SFC-E6K | SFC-E8K | SFC-E10K | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity | Capacity Conditions | A | B | A | B | A | B | A | B | A | B | A | B | |

| Cooling Capacity | W | 4,840 | 3,660 | 6,690 | 5,000 | 7,990 | 6,110 | 9,610 | 7,270 | 12,640 | 9,480 | 15,360 | 11,630 | |

| Kcal/h | 4,160 | 3,150 | 5,750 | 4,300 | 6,870 | 5,250 | 8,260 | 6,250 | 10,870 | 8,150 | 13,210 | 10,000 | ||

| Heating Capacity | W | 9,660 | 5,870 | 13,200 | 7,970 | 15,920 | 9,770 | 19,060 | 11,630 | 24,880 | 15,120 | 29,540 | 18,020 | |

| Kcal/h | 8,310 | 5,050 | 11,350 | 6,850 | 13,690 | 8,400 | 16,390 | 10,000 | 21,390 | 13,000 | 25,400 | 15,500 | ||

| Flow Rate | ℓ/min | 13.9 | 11.0 | 19.2 | 14.0 | 23.0 | 18.0 | 27.6 | 21.0 | 36.3 | 27.0 | 44.0 | 33.3 | |

| Head Loss | mAq | 3.1 | 2.0 | 6.0 | 3.2 | 2.1 | 1.3 | 3.1 | 1.8 | 5.5 | 3.0 | 13.4 | 7.7 | |

| Fan Blower | Type | Single Suction TURBO type | ||||||||||||

| SIZE | A | Ø480 | ||||||||||||

| Airflow Volume | ㎥/min | 13 | 16 | 19 | 22 | 26 | 33 | |||||||

| Drive Type | Direct Drive Motor | |||||||||||||

| Quantity | EA | 1 | ||||||||||||

| Motor | Type | BLDC Semi-Enclosed Type (8 poles, Class E insulation) | ||||||||||||

| Power Consumption | W | 20 | 37 | 55 | 80 | 125 | 186 | |||||||

| Quantity | EA | 1 | ||||||||||||

| Heat Exchanger | Type | Integrated Multi-Pass Cross Finned Tube(Slit Fin) | ||||||||||||

| Pipe | Inlet | A | PF 3/4" (20A) | |||||||||||

| Outlet | A | PF 3/4" (20A) | ||||||||||||

| Drain | Ø16 (Outer Diameter) / Built-in Drain Pump (10 W) / Head 600 mm (from Outlet) | |||||||||||||

| External Material | Main Body: Expanded PolyPropylene / Grille Panel : Injection Molded(HIPS, ABS Material) | |||||||||||||

| Air Volume Control | Turbo, Strong, Medium, Weak, Automatic Wireless Remote Controller (Wired remote controller is optional) | |||||||||||||

| Power Supply | Single Phase 220V 60HZ | |||||||||||||

| AIR FILTER | Vinyl Chloride (Flush type) | |||||||||||||

| Discharge Swing Motor | DC 12V STEPPING MOTOR | |||||||||||||

| Dimensions | Main Body | DxWxH (mm) |

835 X 835 X 274.5 | |||||||||||

| Panel | 950 X 950 X 35 | |||||||||||||

| Product Weight | Kg | 15 | 17 | 20 | ||||||||||

| * Note | 1. Capacity Condition A - Cooling Capacity When indoor air is DB 27°C, WB 21°C, and inlet water temperature is 5°C Heating Capacity When indoor air is 18°C, and inlet water temperature is 80°C 2. Capacity Condition B - Cooling Capacity: When indoor air is DB 27°C, WB 19.5°C, and inlet water temperature is 7°C Heating Capacity: When indoor air is 21 °C, and inlet water temperature is 60°C |

|||||||||||||

A wireless remote controller is included as a standard feature, offering three fan speed settings (Strong, Medium, Weak) and Turbo mode for rapid cooling and heating

Uses high airflow, low noise Turbo Fans.

A drain check valve is installed as standard to prevent the backflow of condensate.

With application of a BLDC motor as a standard specification

power consumption can be reduced by more than 30% compared to an AC motor with low power and high efficiency.

An automatic drain pump is built-in. (600 mm of drainage capability).

For energy savings, installation of On/Off valves for each product is recommended.Option

These control the flow in coordination with the unit's operation preventing condensation issues during cooling, and reducing unnecessary operation cycles of the circulation pump

Both central control and group control are available.Option

Central control can be achieved through power line communication and S-485 communication

Group control of up to 16 units can be performed using a wired remote controller.

The use of UV lamps provides outstanding effects in terms of sterilization antibacterial properties, odor removal, and addressing sick building syndrome.Option

Korean Patent Registration No. 10-1147406

| No. | DESCRIPTION | MAT'L | Q'TY | REMARK |

|---|---|---|---|---|

| 1 | BODY CASE | GI | 1 | - |

| 2 | COOL WATER OUTLET | BS | 1 | PF3/4"(20A) |

| 3 | COOL WATER INLET | BS | 1 | PF3/4"(20A) |

| 4 | AIR VENT | BS | 1 | PF3/4"(20A) |

| 5 | HOT WATER OUTLET | BS | 1 | PF3/4"(20A) |

| 6 | HOT WATER INLET | BS | 1 | PT 1/8"(SLIDING TYPE) |

| 7 | STEPPING MOTOR | ASS'Y | 1 | DC12V, 15Ω |

| 8 | DRAIN PUMP | ASS’Y | 1 | 1Ø, 220V, 60Hz |

| 9 | DRAIN PIPE PORT | - | 1 | Ø16(Outer Diameter) |

| 10 | MOTOR | - | 1 | BLDC |

| 11 | BLOWER | SAN G20% | 1 | - |

| 12 | BLADE | ABS/HIPS | 4 | WHITE BEIGE |

| 13 | SUCTION GRILL | ABS/HIPS | 1 | WHITE BEIGE |

| 14 | INTERIOR GRILLE ASS'Y | ABS/HIPS | 1 | WHITE BEIGE |

| 15 | REMOTE CONTROL RECEIVER | ACRYLIC | 1 | SLIDING TYPE |

| 16 | GRILLE REMOVAL BUTTON | ABS/HIPS | 2 | SLIDING TYPE |

| 17 | HANGING BRACKET | GI | 4 | - |

| Category | Specifications | SFC-2K2 | SFC-3K2 | SFC-4K2 | SFC-5K2 | SFC-6K2 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity | Capacity Conditions | A | B | A | B | A | B | A | B | A | B | |||

| Cooling Capacity | W | 3,030 | 2,340 | 4,640 | 3,520 | 6,170 | 4,710 | 7,650 | 5,850 | 9,200 | 6,980 | |||

| Kcal/h | 2,620 | 2,010 | 3,990 | 3,030 | 5,310 | 4,050 | 6,580 | 5,030 | 7,900 | 6,000 | ||||

| Heating Capacity | W | 5,130 | 3,020 | 6,340 | 3,710 | 8,930 | 5,230 | 11,020 | 6,400 | 12,150 | 6,980 | |||

| Kcal/h | 4,410 | 2,600 | 5,460 | 3,190 | 7,680 | 4,500 | 9,480 | 5,500 | 10,450 | 6,000 | ||||

| Flow Rate | ℓ/min | 8.9/7.4 | 6.8/4.4 | 13.3/9.1 | 10.2/5.4 | 17.8/12.9 | 13.6/7.6 | 22.0/15.9 | 16.8/9.2 | 26.4/17.5 | 20.1/10.1 | |||

| Head Loss | mAq | 2.46/0.85 | 1.44/0.3 | 5.49/2.75 | 3.23/0.45 | 9.84/4.92 | 5.74/0.9 | 15.0/3.9 | 8.8/1.3 | 21.6/4.8 | 3.17/1.58 | |||

| Fan Blower | Type | Single Suction TURBO type | ||||||||||||

| SIZE | A | Ø480 | ||||||||||||

| Airflow Volume | ㎥/min | 6 | 9.5 | 13 | 16 | 26 | ||||||||

| Drive Type | Direct Drive Motor | |||||||||||||

| Quantity | EA | 1 | ||||||||||||

| Motor | Type | BLDC Semi-Enclosed Type (8 poles, Class E insulation) | ||||||||||||

| Power Consumption | W | 40 | 44 | 51 | 56 | 130 | ||||||||

| Quantity | EA | 1 | ||||||||||||

| Heat Exchanger | Type | Integrated Multi-Pass Cross Finned Tube(Slit Fin) | ||||||||||||

| Pipe | Inlet | A | PF 3/4" (20A) | |||||||||||

| Outlet | A | PF 3/4" (20A) | ||||||||||||

| Drain | Ø16 (Outer Diameter) / Built-in Drain Pump (10 W) / Head 600 mm (from Outlet) | |||||||||||||

| External Material | Main Body: Zinc-Coated Steel Plate / Grille Panel: Injection Molded (HIPS, ABS Material) | |||||||||||||

| Air Volume Control | Turbo, Strong, Medium, Weak, Automatic Wireless Remote Controller (Wired remote controller is optional) | |||||||||||||

| Power Supply | Single Phase 220V 60HZ | |||||||||||||

| AIR FILTER | Vinyl Chloride (Flush type) | |||||||||||||

| Discharge Swing Motor | DC 12V STEPPING MOTOR | |||||||||||||

| Dimensions | Main Body | DxWxH (mm) |

830 X 830 X 250 | |||||||||||

| Panel | 950 X 950 X 35 | |||||||||||||

| Product Weight | Kg | 36 | 36.5 | 37.5 | ||||||||||

| * Note | 1. Capacity Condition A - Cooling Capacity When indoor air is DB 27°C, WB 21°C, and inlet water temperature is 5°C Heating Capacity When indoor air is 18°C, and inlet water temperature is 80°C 2. Capacity Condition B - Cooling Capacity: When indoor air is DB 27°C, WB 19.5°C, and inlet water temperature is 7°C Heating Capacity: When indoor air is 21 °C, and inlet water temperature is 60°C |

|||||||||||||

An automatic drain pump is built-in (600 mm of drainage capability).

A drain check valve is installed as standard to prevent the backflow of condensate.Option

An independent control grille panel can be installed.Option

With the application of a BLDC motor as a standard specification, power consumption can be reduced by more than 30% compared to an AC motor with low power and high efficiency.

Both central control and group control are available.Option

Central control can be achieved through power line communication and S-485 communication

Group control of up to 16 units can be performed using a wired remote controller.

A wireless remote controller is included as a standard feature, offering three fan speed settings (Strong, Medium, Weak) and Turbo mode for rapid cooling and heating

For energy savings, installation of On/Off valves for each product is recommended.

These control the flow in coordination with the unit's operation preventing condensation issues during cooling, and reducing unnecessary operation cycles of the circulation pump

The use of UV lamps provides outstanding effects in terms of sterilization antibacterial properties, odor removal, and addressing sick building syndrome.Option

Korean Patent Registration No. 10-1147406

| No. | DESCRIPTION | MAT'L | Q'TY | REMARK |

|---|---|---|---|---|

| 1 | BODY CASE | GI | 1 | - |

| 2 | WATER OUTLET | BS | 1 | PF3/4"(20A) |

| 3 | AIR VENT | BS | 1 | PT 1/8"(SLIDING TYPE) |

| 4 | WATER INLET | BS | 1 | PF3/4"(20A) |

| 5 | STEPPING MOTOR | ASS'Y | 1 | DC12V, 15Ω |

| 6 | DRAIN PUMP | ASS’Y | 1 | 1Ø, 220V, 60Hz |

| 7 | DRAIN PIPE PORT | - | 1 | Ø16(Outer Diameter) |

| 8 | MOTOR | - | 1 | BLDC |

| 9 | BLOWER | SAN G20% | 1 | - |

| 10 | BLADE | ABS/HIPS | 2 | WHITE BEIGE |

| 11 | SUCTION GRILL | ABS/HIPS | 1 | WHITE BEIGE |

| 12 | INTERIOR GRILLE ASS'Y | ABS/HIPS | 1 | WHITE BEIGE |

| 13 | REMOTE CONTROL RECEIVER | ACRYLIC | 1 | SLIDING TYPE |

| 14 | GRILLE REMOVAL BUTTON | ABS/HIPS | 2 | SLIDING TYPE |

| 15 | HANGING BRACKET | GI | 4 | - |

| Category | Specifications | SFC-ES2.5K | SFC-ES3K | SFC-ES3.5K | ||||

|---|---|---|---|---|---|---|---|---|

| Capacity | Capacity Conditions | A | B | A | B | A | B | |

| Cooling Capacity | W | 4,830 | 3,660 | 6,400 | 4,880 | 7,580 | 5,810 | |

| Kcal/h | 4,150 | 3,150 | 5,500 | 4,200 | 6,520 | 5,000 | ||

| Heating Capacity | W | 9,600 | 5,870 | 11,990 | 7,370 | 13,800 | 8,490 | |

| Kcal/h | 8,260 | 5,050 | 10,310 | 6,340 | 11,870 | 7,300 | ||

| Flow Rate | ℓ/min | 13.9 | 11.0 | 18.4 | 14.0 | 21.8 | 18.0 | |

| Head Loss | mAq | 4.6 | 2.9 | 8.0 | 4.6 | 13.1 | 7.6 | |

| Fan Blower | Type | Single Suction TURBO type | ||||||

| SIZE | A | Ø325 | ||||||

| Airflow Volume | ㎥/min | 11 | 13 | 16 | ||||

| Drive Type | Direct Drive Motor | |||||||

| Quantity | EA | 1 | ||||||

| Motor | Type | BLDC Semi-Hermetic Type (8-Pole, Class E Insulation) | ||||||

| Power Consumption | W | 52 | 67 | 105 | ||||

| Quantity | EA | 1 | ||||||

| Heat Exchanger | Type | Integrated Multi-Pass Cross Finned Tube(Slit Fin) | ||||||

| Pipe | Inlet | A | 20A | |||||

| Outlet | A | 20A | ||||||

| Drain | Ø16 (Outer Diameter) / Built-in Drain Pump (10 W) / Head 600 mm (from Outlet) | |||||||

| External Material | Main Body: Zinc-Coated Steel Plate / Grille Panel: Injection Molded (HIPS, ABS Material) | |||||||

| Air Volume Control | Turbo, Strong, Medium, Weak, Automatic Wireless Remote Controller (Wired remote controller is optional) | |||||||

| Power Supply | Single Phase 220V 60HZ | |||||||

| AIR FILTER | Vinyl Chloride (Flush type) | |||||||

| Discharge Swing Motor | DC 12V STEPPING MOTOR | |||||||

| Exterior | Main Body | DxWxH (mm) |

562 X 884 X 239.5 | |||||

| Panel | 1030 X 660 X 35 | |||||||

| Product Weight | Kg | 22.5 | ||||||

| * Note | 1. Capacity Condition A - Cooling Capacity When indoor air is DB 27°C, WB 21°C, and inlet water temperature is 5°C Heating Capacity When indoor air is 18°C, and inlet water temperature is 80°C 2. Capacity Condition B - Cooling Capacity: When indoor air is DB 27°C, WB 19.5°C, and inlet water temperature is 7°C Heating Capacity: When indoor air is 21 °C, and inlet water temperature is 60°C |

|||||||

A wireless remote controller is included as a standard feature, offering three fan speed settings (Strong, Medium, Weak) and Turbo mode for rapid cooling and heating

Uses high airflow, low noise Turbo Fans.

A drain check valve is installed as standard to prevent the backflow of condensate.

With application of a BLDC motor as a standard specification

power consumption can be reduced by more than 30% compared to an AC motor with low power and high efficiency.

An automatic drain pump is built-in. (600 mm of drainage capability).

For energy savings, installation of On/Off valves for each product is recommended.Option

These control the flow in coordination with the unit's operation preventing condensation issues during cooling, and reducing unnecessary operation cycles of the circulation pump

Both central control and group control are available.Option

Central control can be achieved through power line communication and S-485 communication

Group control of up to 16 units can be performed using a wired remote controller.

The use of UV lamps provides outstanding effects in terms of sterilization antibacterial properties, odor removal, and addressing sick building syndrome.Option

Korean Patent Registration No. 10-1147406

| No. | DESCRIPTION | MAT'L | Q'TY | REMARK |

|---|---|---|---|---|

| 1 | BODY CASE | EPP | 1 | - |

| 2 | WATER OUTLET | BS | 1 | PF3/4"(20A) |

| 3 | AIR VENT | BS | 1 | PT 1/8"(SLIDING TYPE) |

| 4 | WATER INLET | BS | 1 | PF3/4"(20A) |

| 5 | STEPPING MOTOR | ASS'Y | 1 | DC12V, 15Ω |

| 6 | DRAIN PUMP | ASS’Y | 1 | 1Ø, 220V, 60Hz |

| 7 | DRAIN PIPE PORT | - | 1 | Ø16(Outer Diameter) |

| 8 | MOTOR | - | 1 | BLDC |

| 9 | BLOWER | SAN G20% | 1 | - |

| 10 | BLADE | ABS/HIPS | 2 | WHITE BEIGE |

| 11 | SUCTION GRILL | ABS/HIPS | 1 | WHITE BEIGE |

| 12 | INTERIOR GRILLE ASS'Y | ABS/HIPS | 1 | WHITE BEIGE |

| 13 | REMOTE CONTROL RECEIVER | ACRYLIC | 1 | SLIDING TYPE |

| 14 | GRILLE REMOVAL BUTTON | ABS/HIPS | 2 | SLIDING TYPE |

| 15 | HANGING BRACKET | EPP | 4 | - |

| Category | Specifications | SFC2-E3K | SFC2-E4K | SFC2-E5K | ||||

|---|---|---|---|---|---|---|---|---|

| Capacity | Capacity Conditions | A | B | A | B | A | B | |

| Cooling Capacity | W | 4,830 | 3,660 | 6,400 | 4,880 | 7,580 | 5,810 | |

| Kcal/h | 4,150 | 3,150 | 5,500 | 4,200 | 6,520 | 5,000 | ||

| Heating Capacity | W | 9,600 | 5,870 | 11,990 | 7,370 | 13,800 | 8,490 | |

| Kcal/h | 8,260 | 5,050 | 10,310 | 6,340 | 11,870 | 7,300 | ||

| Flow Rate | ℓ/min | 13.9 | 11.0 | 18.4 | 14.0 | 21.8 | 18.0 | |

| Head Loss | mAq | 4.6 | 2.9 | 8.0 | 4.6 | 13.1 | 7.6 | |

| Fan Blower | Type | Single Suction TURBO type | ||||||

| SIZE | A | Ø325 | ||||||

| Airflow Volume | ㎥/min | 11 | 13 | 16 | ||||

| Drive Type | Direct Drive Motor | |||||||

| Quantity | EA | 1 | ||||||

| Motor | Type | BLDC Semi-Hermetic Type (8-Pole, Class E Insulation) | ||||||

| Power Consumption | W | 52 | 67 | 105 | ||||

| Quantity | EA | 1 | ||||||

| Heat Exchanger | Type | Integrated Multi-Pass Cross Finned Tube(Slit Fin) | ||||||

| Pipe | Inlet | A | PF 3/4" (20A) | |||||

| Outlet | A | PF 3/4" (20A) | ||||||

| Drain | Ø16 (Outer Diameter) / Built-in Drain Pump (10 W) / Head 600 mm (from Outlet) | |||||||

| External Material | Main Body: Expanded PolyPropylene / Grille Panel: Injection Molded (HIPS, ABS Material) | |||||||

| Air Volume Control | Turbo, Strong, Medium, Weak, Automatic Wireless Remote Controller (Wired remote controller is optional) | |||||||

| Power Supply | Single Phase 220V 60HZ | |||||||

| AIR FILTER | Vinyl Chloride (Flush type) | |||||||

| Discharge Swing Motor | DC 12V STEPPING MOTOR | |||||||

| Exterior | Main Body | DxWxH (mm) |

591 X 973 X271 | |||||

| Panel | 1030 X 660 X 35 | |||||||

| Product Weight | Kg | 18.5 | ||||||

| * Note | 1. Capacity Condition A - Cooling Capacity When indoor air is DB 27°C, WB 21°C, and inlet water temperature is 5°C Heating Capacity When indoor air is 18°C, and inlet water temperature is 80°C 2. Capacity Condition B - Cooling Capacity: When indoor air is DB 27°C, WB 19.5°C, and inlet water temperature is 7°C Heating Capacity: When indoor air is 21 °C, and inlet water temperature is 60°C |

|||||||

A wireless remote controller is included as a standard feature, offering three fan speed settings (Strong, Medium, Weak) and Turbo mode for rapid cooling and heating

Uses high airflow, low noise Turbo Fans.

A drain check valve is installed as standard to prevent the backflow of condensate.

With the application of a BLDC motor as standard a specification

power consumption can be reduced by more than 30% compared to an AC motor with low power and high efficiency.

An automatic drain pump is built-in. (600 mm of drainage capability).

For energy savings, installation of On/Off valves for each product is recommended. Option

These control the flow in coordination with the unit's operation preventing condensation issues during cooling, and reducing unnecessary operation cycles of the circulation pump

Both central control and group control are available.Option

Central control can be achieved through power line communication and S-485 communication

Group control of up to 16 units can be performed using a wired remote controller.

The use of UV lamps provides outstanding effects in terms of sterilization antibacterial properties, odor removal, and addressing sick building syndrome.Option

Korean Patent Registration No. 10-1147406

| No. | DESCRIPTION | MAT'L | Q'TY | REMARK |

|---|---|---|---|---|

| 1 | BODY CASE | GI | 1 | - |

| 2 | COOL WATER OUTLET | BS | 1 | PF3/4"(20A) |

| 3 | COOL WATER INLET | BS | 1 | PF3/4"(20A) |

| 4 | AIR VENT | BS | 1 | PT 1/8"(SLIDING TYPE) |

| 5 | HOT WATER OUTLET | BS | 1 | PF3/4"(20A) |

| 6 | HOT WATER INLET | BS | 1 | PT 1/8"(SLIDING TYPE) |

| 7 | STEPPING MOTOR | ASS'Y | 1 | DC12V, 15Ω |

| 8 | DRAIN PUMP | ASS’Y | 1 | 1Ø, 220V, 60Hz |

| 9 | DRAIN PIPE PORT | - | 1 | Ø16(Outer Diameter) |

| 10 | MOTOR | - | 1 | BLDC |

| 11 | BLOWER | SAN G20% | 1 | - |

| 12 | BLADE | ABS/HIPS | 2 | WHITE BEIGE |

| 13 | SUCTION GRILL | ABS/HIPS | 1 | WHITE BEIGE |

| 14 | INTERIOR GRILLE ASS'Y | ABS/HIPS | 1 | WHITE BEIGE |

| 15 | REMOTE CONTROL RECEIVER | ACRYLIC | 1 | SLIDING TYPE |

| 16 | GRILLE REMOVAL BUTTON | ABS/HIPS | 2 | SLIDING TYPE |

| 17 | HANGING BRACKET | GI | 4 | - |

| Category | Specifications | SFC2-3K2 | SFC2-4K2 | SFC2-5K2 | ||||

|---|---|---|---|---|---|---|---|---|

| Capacity | Capacity Conditions | A | B | A | B | A | B | |

| Cooling Capacity | W | 4,730 | 3,630 | 6,090 | 4,630 | 6,710 | 5,080 | |

| Kcal/h | 4,070 | 3,120 | 5,240 | 3,980 | 5,770 | 4,370 | ||

| Heating Capacity | W | 6,280 | 3,700 | 7,930 | 4,630 | 8,800 | 5,080 | |

| Kcal/h | 5,400 | 3,180 | 6,820 | 3,980 | 7,570 | 4,370 | ||

| Flow Rate | ℓ/min | 13.6/9.0 | 10.5/5.4 | 17.5/11.4 | 13.3/6.7 | 19.3/11.4 | 14.6/12.7 | |

| Head Loss | mAq | 4.36/0.96 | 2.60/0.34 | 7.22/1.53 | 4.17/0.53 | 8.79/1.53 | 5.03/1.9 | |

| Fan Blower | Type | Single Suction TURBO type | ||||||

| SIZE | A | Ø325 | ||||||

| Airflow Volume | ㎥/min | 8 | 13 | 16 | ||||

| Drive Type | Direct Drive Motor | |||||||

| Quantity | EA | 1 | ||||||

| Motor | Type | Main Body: Zinc-Coated Steel Plate / Grille Panel: Injection Molded (HIPS, ABS Material) | ||||||

| Power Consumption | W | 36 | 50 | 92 | ||||

| Quantity | EA | 1 | ||||||

| Heat Exchanger | Type | Integrated Multi-Pass Cross Finned Tube(Slit Fin) | ||||||

| Pipe | Inlet | A | PF 3/4" (20A) | |||||

| Outlet | A | PF 3/4" (20A) | ||||||

| Drain | Ø16 (Outer Diameter) / Built-in Drain Pump (10 W) / Head 600 mm (from Outlet) | |||||||

| External Material | Main Body: Zinc-Coated Steel Plate (0.8 t, 1.0 t) / Grille Panel: Injection Molded (HIPS, ABS Material) | |||||||

| Air Volume Control | Turbo, Strong, Medium, Weak, Automatic Wireless Remote Controller (Wired remote controller is optional) | |||||||

| Power Supply | Single Phase 220V 60HZ | |||||||

| AIR FILTER | Vinyl Chloride (Flush type) | |||||||

| Discharge Swing Motor | DC 12V STEPPING MOTOR | |||||||

| Exterior | Main Body | DxWxH (mm) |

562 X 884 X 239.5 | |||||

| Panel | 1030 X 660 X 35 | |||||||

| Product Weight | Kg | 32 | ||||||

| * Note | 1. Capacity Condition A - Cooling Capacity When indoor air is DB 27°C, WB 21°C, and inlet water temperature is 5°C Heating Capacity When indoor air is 18°C, and inlet water temperature is 80°C 2. Capacity Condition B - Cooling Capacity: When indoor air is DB 27°C, WB 19.5°C, and inlet water temperature is 7°C Heating Capacity: When indoor air is 21 °C, and inlet water temperature is 60°C |

|||||||

An automatic drain pump is built-in (600 mm of drainage capability).

A drain check valve is installed as standard to prevent the backflow of condensate.

With the application of a BLDC motor as a standard specification, power consumption can be reduced by more than 30% compared to an AC motor with low power and high efficiency.

Both central control and group control are available.Option

Central control can be achieved through power line communication and S-485 communication

Group control of up to 16 units can be performed using a wired remote controller.

A wireless remote controller is included as a standard feature, offering three fan speed settings (Strong, Medium, Weak) and Turbo mode for rapid cooling and heating

For energy savings, installation of On/Off valves for each product is recommended.

These control the flow in coordination with the unit's operation preventing condensation issues during cooling, and reducing unnecessary operation cycles of the circulation pump

The use of UV lamps provides outstanding effects in terms of sterilization antibacterial properties, odor removal, and addressing sick building syndrome.Option

Korean Patent Registration No. 10-1147406

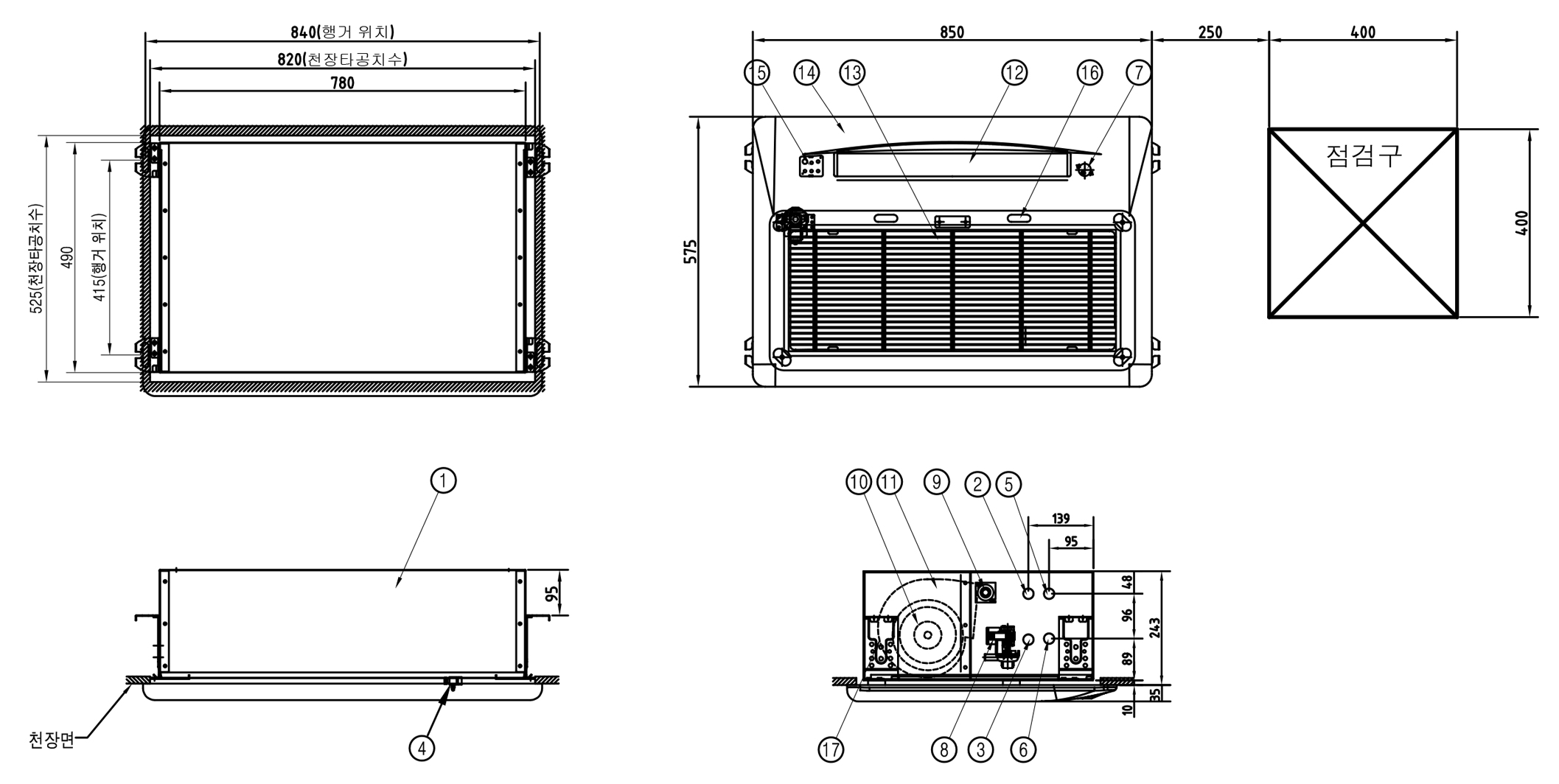

| No. | DESCRIPTION | MAT'L | Q'TY | REMARK |

|---|---|---|---|---|

| 1 | BODY CASE | GI | 1 | - |

| 2 | WATER OUTLET | BS | 1 | PF3/4"(20A) |

| 3 | AIR VENT | BS | 1 | PT 1/8"(SLIDING TYPE) |

| 4 | WATER INLET | BS | 1 | PF3/4"(20A) |

| 5 | STEPPING MOTOR | ASS'Y | 1 | DC12V, 15Ω |

| 6 | DRAIN PUMP | ASS’Y | 1 | 1Ø, 220V, 60Hz |

| 7 | DRAIN PIPE PORT | - | 1 | Ø16(Outer Diameter) |

| 8 | MOTOR | - | 1 | BLDC |

| 9 | BLOWER | SAN G20% | 1 | - |

| 10 | BLADE | ABS/HIPS | 1 | WHITE BEIGE |

| 11 | SUCTION GRILL | ABS/HIPS | 1 | WHITE BEIGE |

| 12 | INTERIOR GRILLE ASS'Y | ABS/HIPS | 1 | WHITE BEIGE |

| 13 | REMOTE CONTROL RECEIVER | ACRYLIC | 1 | SLIDING TYPE |

| 14 | GRILLE REMOVAL BUTTON | ABS/HIPS | 2 | SLIDING TYPE |

| 15 | HANGING BRACKET | GI | 4 | - |

| Category | Specifications | SFC1-1.5KB | SFC1-2KB | SFC1-2.5KB | SFC1-3KB | SFC1-3.5KB | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity | Capacity Conditions | A | B | A | B | A | B | A | B | A | B | |||

| Cooling Capacity | W | 2,450 | 1,860 | 3,210 | 2,440 | 3,840 | 2,910 | 4,730 | 3,610 | 5,360 | 4,070 | |||

| Kcal/h | 2,110 | 1,600 | 2,760 | 2,100 | 3,300 | 2,500 | 4,070 | 3,100 | 4,610 | 3,500 | ||||

| Heating Capacity | W | 4,880 | 2,980 | 6,070 | 3,720 | 7,070 | 4,300 | 8,520 | 5,230 | 10,070 | 6,160 | |||

| Kcal/h | 4,200 | 2,560 | 5,220 | 3,200 | 6,080 | 3,700 | 7,330 | 4,500 | 8,660 | 5,300 | ||||

| Flow Rate | ℓ/min | 7.1 | 5.3 | 9.3 | 7.0 | 11.1 | 8.3 | 13.6 | 10.3 | 15.4 | 11.7 | |||

| Head Loss | mAq | 0.58 | 0.32 | 1 | 0.57 | 1.42 | 0.79 | 3.2 | 1.84 | 4.1 | 2.37 | |||

| Fan Blower | Type | Double Suction SIOCCO Type | ||||||||||||

| SIZE | A | Ø140 x 165 | Ø140 x 200 | Ø140 x 200 | Ø140 x 200 | Ø140 x 200 | ||||||||

| Airflow Volume | ㎥/min | 5.6 | 7 | 9 | 9 | 11 | ||||||||

| Drive Type | Direct Drive Motor | |||||||||||||

| Quantity | EA | 1 | ||||||||||||

| Motor | Type | BLDC Semi-Enclosed Type (8 poles, Class E insulation) | ||||||||||||

| Power Consumption | W | 30 | 41 | 74 | 74 | 108 | ||||||||

| Quantity | EA | 1 | ||||||||||||

| Heat Exchanger | Type | Integrated Multi-Pass Cross Finned Tube(Slit Fin) | ||||||||||||

| Pipe | Inlet | A | PF 3/4" (20A) | |||||||||||

| Outlet | A | PF 3/4" (20A) | ||||||||||||

| Drain | Ø16 (Outer Diameter) / Built-in Drain Pump (10 W) / Head 600 mm (from Outlet) | |||||||||||||

| External Material | Main Body: Zinc-Coated Steel Plate/ Grille Panel: Injection Molded (HIPS, ABS Material) | |||||||||||||

| Air Volume Control | Turbo, Strong, Medium, Weak, Automatic Wireless Remote Controller (Wired remote controller is optional) | |||||||||||||

| Power Supply | Single Phase 220V 60HZ | |||||||||||||

| AIR FILTER | Vinyl Chloride (Flush type) | |||||||||||||

| Discharge Swing Motor | DC 12V STEPPING MOTOR | |||||||||||||

| Dimensions | Main Body | DxWxH (mm) |

490 X 780 X 231 | |||||||||||

| Panel | 575 X 850 X 35 | |||||||||||||

| Product Weight | Kg | 27 | 27 | 28 | 30 | 30 | ||||||||

| * Note | 1. Capacity Condition A - Cooling Capacity When indoor air is DB 27°C, WB 21°C, and inlet water temperature is 5°C Heating Capacity When indoor air is 18°C, and inlet water temperature is 80°C 2. Capacity Condition B - Cooling Capacity: When indoor air is DB 27°C, WB 19.5°C, and inlet water temperature is 7°C Heating Capacity: When indoor air is 21 °C, and inlet water temperature is 60°C |

|||||||||||||

A wireless remote controller is included as a standard feature, offering three fan speed settings (Strong, Medium, Weak) and Turbo mode for rapid cooling and heating

Enables quiet operation by adopting Sirocco Fan.

A drain check valve is installed as standard to prevent the backflow of condensate.

With the application of a BLDC motor as standard a specification

power consumption can be reduced by more than 30% compared to an AC motor with low power and high efficiency.

An automatic drain pump is built-in. (600 mm of drainage capability).

For energy savings, installation of On/Off valves for each product is recommended.Option

These control the flow in coordination with the unit's operation preventing condensation issues during cooling, and reducing unnecessary operation cycles of the circulation pump

Both central control and group control are available.Option

Central control can be achieved through power line communication and S-485 communication

Group control of up to 16 units can be performed using a wired remote controller.

The use of UV lamps provides outstanding effects in terms of sterilization antibacterial properties, odor removal, and addressing sick building syndrome.Option

Korean Patent Registration No. 10-1147406

| No. | DESCRIPTION | MAT'L | Q'TY | REMARK |

|---|---|---|---|---|

| 1 | BODY CASE | GI | 1 | - |

| 2 | COOL WATER OUTLET | BS | 1 | PF3/4"(20A) |

| 3 | COOL WATER INLET | BS | 1 | PT 1/8"(SLIDING TYPE) |

| 4 | AIR VENT | BS | 1 | PT 1/8"(SLIDING TYPE) |

| 5 | HOT WATER OUTLET | BS | 1 | PF3/4"(20A) |

| 6 | HOT WATER INLET | BS | 1 | PT 1/8"(SLIDING TYPE) |

| 7 | STEPPING MOTOR | ASS'Y | 1 | DC12V, 15Ω |

| 8 | DRAIN PUMP | ASS’Y | 1 | 1Ø, 220V, 60Hz |

| 9 | DRAIN PIPE PORT | - | 1 | Ø16(Outer Diameter) |

| 10 | MOTOR | - | 1 | BLDC |

| 11 | BLOWER | SAN G20% | 1 | - |

| 12 | BLADE | ABS/HIPS | 1 | WHITE BEIGE |

| 13 | SUCTION GRILL | ABS/HIPS | 1 | WHITE BEIGE |

| 14 | INTERIOR GRILLE ASS'Y | ABS/HIPS | 1 | WHITE BEIGE |

| 15 | REMOTE CONTROL RECEIVER | ACRYLIC | 1 | SLIDING TYPE |

| 16 | GRILLE REMOVAL BUTTON | ABS/HIPS | 2 | SLIDING TYPE |

| 17 | HANGING BRACKET | GI | 4 | - |

| Category | Specifications | SFC1-1.5K2 | SFC1-2K2 | SFC1-3K2 | ||||

|---|---|---|---|---|---|---|---|---|

| Capacity | Capacity Conditions | A | B | A | B | A | B | |

| Cooling Capacity | W | 2,460 | 1,860 | 3,380 | 2,570 | 4,300 | 3,240 | |

| Kcal/h | 2,120 | 1,600 | 2,910 | 2,210 | 3,700 | 2,790 | ||

| Heating Capacity | W | 2,780 | 1,620 | 3,620 | 2,080 | 4,420 | 2,510 | |

| Kcal/h | 2,390 | 1,390 | 3,110 | 1,790 | 3,800 | 2,160 | ||

| Flow Rate | ℓ/min | 7.1/4.0 | 5.5/2.4 | 9.7/5.2 | 7.4/3.0 | 12.4/6.4 | 9.4/3.7 | |

| Head Loss | mAq | 0.5/0.63 | 0.3/0.23 | 0.93/1.07 | 0.54/0.36 | 1.52/1.62 | 0.87/0.54 | |

| Fan Blower | Type | Double Inlet Sirocco Type | ||||||

| SIZE | A | Ø140 X 165 | Ø140 X 200 | Ø140 X 200 | ||||

| Airflow Volume | ㎥/min | 4 | 7 | 11 | ||||

| Drive Type | Direct Drive Motor | |||||||

| Quantity | EA | 1 | 2 | |||||

| Motor | Type | BLDC Semi-Enclosed Type (8 poles, Class E insulation) | ||||||

| Power Consumption | W | 30 | 35 | 40 | ||||

| Quantity | EA | 1 | ||||||

| Heat Exchanger | Type | Integrated Multi-Pass Cross Finned Tube(Slit Fin) | ||||||

| Pipe | Inlet | A | PF 3/4" (20A) | |||||

| Outlet | A | PF 3/4" (20A) | ||||||

| Drain | Ø16 (Outer Diameter) / Built-in Drain Pump (10 W) / Head 600 mm (from Outlet) | |||||||

| External Material | Main Body: Zinc-Coated Steel Plate / Grille Panel: Injection Molded (HIPS, ABS Material) | |||||||

| Air Volume Control | Turbo, Strong, Medium, Weak, Automatic Wireless Remote Controller (Wired remote controller is optional) | |||||||

| Power Supply | Single Phase 220V 60HZ | |||||||

| AIR FILTER | Vinyl Chloride (Flush type) | |||||||

| Discharge Swing Motor | DC 12V STEPPING MOTOR | |||||||

| Exterior | Main Body | DxWxH (mm) |

490 X 780 X 231 | |||||

| Panel | 575X 850 X 35 | |||||||

| Product Weight | Kg | 29 | 31 | |||||

| * Note | 1. Capacity Condition A - Cooling Capacity When indoor air is DB 27°C, WB 21°C, and inlet water temperature is 5°C Heating Capacity When indoor air is 18°C, and inlet water temperature is 80°C 2. Capacity Condition B - Cooling Capacity: When indoor air is DB 27°C, WB 19.5°C, and inlet water temperature is 7°C Heating Capacity: When indoor air is 21 °C, and inlet water temperature is 60°C |

|||||||

The airflow control grille is made of aluminum, and EPS is used as the insulation material inside the product, making it lightweight. The height of the unit can be adjusted up to 70 mm depending on the ceiling height at the installation site.

With the application of a BLDC motor as a standard specification, power consumption can be reduced by more than 30% compared to an AC motor with low power and high efficiency.Option

A MICOM wireless remote controller switch can be attached. Option

For energy savings, installation of On/Off valves for each product is recommended. Option

These control the flow in coordination with the unit's operation preventing condensation issues during cooling, and reducing unnecessary operation cycles of the circulation pump

The use of UV lamps provides outstanding effects in terms of sterilization antibacterial properties, odor removal, and addressing sick building syndrome.Option

Korean Patent Registration No. 10-1147406

| MODEL | A | B | C | D | E | Ceiling Hole Dimensions | Fully Threaded Bolt Dimensions |

|---|---|---|---|---|---|---|---|

| SFC-20CC | 856 | 796 | 530 | 538 | 1 | 520 x 828 | 442 x 537 |

| SFC-30CC | 986 | 926 | 660 | 668 | 1 | 520 x 958 | 442 x 667 |

| SFC-40CC | 1136 | 1076 | 810 | 818 | 2 | 520 x 1108 | 442 x 817 |

| SFC-60CC | 1446 | 1386 | 1120 | 1128 | 2 | 520 x 1418 | 442 x 1127 |

| SFC-80CC | 1756 | 1696 | 1430 | 1438 | 3 | 520 x 1728 | 442 x 1437 |

| No. | DESCRIPTION | MAT'L | Q'TY | REMARK |

|---|---|---|---|---|

| 1 | WATER OUTLET | BS | 1 | PF 3/4"(20A) |

| 2 | AIR VENT | BS | 1 | PT 1/8"(SLIDING TYPE) |

| 3 | WATER INLET | BS | 1 | PF 3/4"(20A) |

| 4 | DRAIN PAN | CR | 1 | Powder Coating |

| 5 | DRAIN CONNECTION | - | 1 | NIPPLE 3/4"(20A) |

| 6 | FAN & HOUSING | ASSY | E | SIROCCO FAN |

| 7 | BODY SIDE PLATE | GI | 2 | - |

| 8 | TERMINAL BLOCK | - | 1 | 20A, 6P |

| 9 | GRILLE PANEL | CR+AL | 1 | Powder Coating |

| 10 | Air Volume Control GRILLE | AL | 2 | Powder Coating |

| 11 | SERVICE PANEL | CR | 1 | Powder Coating |

| 12 | AIR CHAMBER | Styrofoam | 1 | - |

| 13 | AIR FILTER | ACRYLIC | 1 | SLIDING TYPE |

| 14 | HEAT & COOLING COIL | CU-AL | 1 | SLIT FIN |

| Category | Specifications | SFC-20CC | SFC-30CC | SFC-40CC | SFC-60CC | SFC-80CC | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity | Capacity Conditions | A | B | A | B | A | B | A | B | A | B | |||

| Cooling Capacity | W | 2,790 | 2,120 | 3,700 | 2,810 | 5,360 | 4,050 | 7,220 | 5,490 | 10,440 | 7,870 | |||

| Kcal/h | 2,400 | 1,820 | 3,180 | 2,420 | 4,610 | 3,480 | 6,210 | 4,720 | 8,980 | 6,770 | ||||

| Heating Capacity | W | 5,640 | 3,470 | 7,780 | 4,770 | 10,990 | 6,710 | 14,330 | 8,760 | 21,240 | 12,950 | |||

| Kcal/h | 4,850 | 2,980 | 6,690 | 4,100 | 9,450 | 5,770 | 12,320 | 7,530 | 18,270 | 11,140 | ||||

| Flow Rate | ℓ/min | 8.1 | 6.0 | 10.7 | 8.0 | 15.4 | 11.5 | 20.8 | 15.7 | 30.0 | 22.4 | |||

| Head Loss | mAq | 0.7 | 0.4 | 1.6 | 1.9 | 4.4 | 2.4 | 3.5 | 2.0 | 9.5 | 5.3 | |||

| Fan Blower | Type | Double Suction Multiblade (SOCCO FAN) | ||||||||||||

| SIZE | A | Ø192 X L170 | Ø192 X L200 | Ø192 X L170 | Ø192 X L200 | Ø192 X L200 | ||||||||

| Airflow Volume | ㎥/min | 5.7 | 8.5 | 11.3 | 17 | 22.6 | ||||||||

| Drive Type | Direct Drive Motor | |||||||||||||

| Quantity | EA | 1 | 1 | 2 | 2 | 3 | ||||||||

| Motor | Type | AC Semi-Enclosed Type (6 poles, Class B insulation | ||||||||||||

| Power Consumption | W | 45 | 55 | 75 | 95 | 150 | ||||||||

| Quantity | EA | 1 | 1 | 1 | 1 | 2 | ||||||||

| Heat Exchanger | Type | Integrated Multi-Pass Cross Finned Tube(Slit Fin) | ||||||||||||

| Pipe | Inlet | A | PF 3/4" (20A) | |||||||||||

| Outlet | A | PF 3/4" (20A) | ||||||||||||

| Drain | NIPPLE 3/4"(20A) | |||||||||||||

| External Material | Galvanized Steel Sheet | |||||||||||||

| Air Volume Control | Strong, Medium, Weak 3-Stage Rotary Switch | |||||||||||||

| Power Supply | Single Phase 220V 60HZ | |||||||||||||

| AIR FILTER | Vinyl Chloride (Submersible Type) | |||||||||||||

| Product Weight | Kg | 23 | 27 | 33 | 39 | 52 | ||||||||

| * Note | 1. Capacity Condition A - Cooling Capacity When indoor air is DB 27°C, WB 21°C, and inlet water temperature is 5°C Heating Capacity When indoor air is 18°C, and inlet water temperature is 80°C 2. Capacity Condition B - Cooling Capacity: When indoor air is DB 27°C, WB 19.5°C, and inlet water temperature is 7°C Heating Capacity: When indoor air is 21 °C, and inlet water temperature is 60°C |

|||||||||||||